Business on chocolate: craft chocolate production mini-factory with a low cost from cocoa liquor.

Tags:

Principle: from cocoa liquor.

Step 1 — Describe the Concept

In our case: a mini-factory for the production of chocolate from grated cocoa. We can produce chocolate bars, chocolate figures, sweets, dragees and pastes.

Let’s start with defining the term cocoa liquor, because there is usually confusion about this issue.

Grated cocoa (cocoa liquor) is not chocolate! This cocoa nibs (roasted, peeled and crushed cocoa beans) which are milled, molded and prepacked. In fact it is a pure, 100% cocoa. It is not chocolate yet (although it looks like chocolate), since to get chocolate you need to add additional ingredients (sugar, for example).

Cocoa mass is sold in the same way as finished chocolate: in the form of blocks, chips and even tiles.

To produce chocolate from grated cocoa, you will need a melanger - mill, which combines several functions: grinding, mixing, conching. A melanger is needed to grind and mix cocoa liquor with the rest of the ingredients in the chocolate and give the chocolate a delicate texture.

Advantages:

- It is profitable to produce chocolate from grated cocoa in comparison with purchased finished chocolate, as the price of cocoa liquor, as a rule, has the price of chocolate or cheaper, and when sugar is added to it, the cost per kg is significantly reduced. However, it is important to understand that this becomes beneficial when the volume of production of chocolate and chocolate products per month exceeds one ton (1000 - 5000 kg)

- High margin: the purchase price of raw materials is 11 EUR. per kg of chocolate - the selling wholesale price can be around 40 - 100 EUR. per kg of finished products;

- A simpler and, as a result, cheaper production process in comparison with Bean-to-bar production. You won’t need a lot of equipment (stoves, crushers, separators), which will make it possible to manage a room with a smaller area. And most importantly: grated production has lower requirements for personnel competencies, as eliminating the need to study the processes of selection of cocoa beans, roast them and bulkheads. For the production of chocolate, you can work only with melangers.

- Compared to a retail store, it can yield significantly higher monthly revenue. Let's suppose you sell your products in bulk with an average price of 40 EUR. kg., produce and sell 1 ton, which is equal to a turnover of 40 000 EUR. per month.

Disadvantages:

- There are no guaranteed sales in comparison with a store with a mini-production, where the buyer will go into the store one way or another and buy at least something. Together with a rather lengthy launch process, in comparison with the store, you must be prepared to spend money for a long time and not have any sales at all. While preparing the room, wait for the equipment, set it up, set up the production of the first batch, it can take half a year, or even more. And you still will not have money, because the real fun begins - when you will start working on your sales of produced product?

- It requires 2-3 times more investments at the start compared to a retail store: you need more space and you need to buy additional professional equipment. 21 000 - 36 000 EUR. to start in a rented room.

- Unlike a store with a mini-production, where you can work without transport packaging, and packaging for products can be simple and not branded, building the production of chocolate products needs to be more thoroughly addressed issues with packaging products. This leads to increased investment at the start and, most importantly, it takes time and competent people to solve this problem.

Advice:

- Do not lose sight of corporate gifts and large individual orders for the holidays. This will significantly help increase business turnover and make a profit. For example: 300 pieces of custom trains for the day of the railroad with a selling price of 35 EUR / pc. will be able to provide a significant increase in monthly revenue. You can also collaborate with flower shops or event-agencies in order to find customers who are ready to place large orders. For example: you can develop a collection of chocolate wedding invitations or a collection of romantic chocolates that can be sold with flowers as an addition.

- Try to clearly define your main value: chocolate for food, chocolate as a gift, chocolate as a healthy food. Choosing one does not mean at all that you can forget about another: you can focus on the healthy chocolate bars, but at the same time produce curly gift chocolate.

I really want to produce chocolate from cocoa beans myself. Is it possible to start with production from grated, and then gradually expand competencies?

This is possible, but in our opinion the commercial value of the production of bean-to-bar lays in the fact that it can be used to build an interactive show program in the format of a museum or an amusement park. And if you build such a production somewhere on the outskirts, then the further use of such a location as a place where people will come will be quite questionable. If you plan to build a bean-to-bar production in the future, then pay attention to:

- Location. The production location should be suitable for the arrival of visitors with the excursion program;

- Layout. The layout of the premises should include end-to-end flow routes for visitors to the factory, a place for administrative premises, a cafe-shop, and other premises necessary for organizing an excursion business.

Is it possible to simultaneously produce tiled chocolate, sweets, pastes and dragees?

Yes, it is possible, but it is necessary to do this launch sequentially. Do not try to run all products at once. Most likely none of the products will be done well. We recommend choosing one product that you most believe in, which is guaranteed to bring you sales and profits. After the successful development of one product, you can move on to another.

Step 2 — Suppliers

In order to supply ingredients in the future, you will need suppliers who sell goods in larger packaging and are either producers of ingredients or companies which are as close as possible to the supply chain.

Advice:

- We recommend that you pay attention to the grated cocoa producers Luker and Cargill among other brands, because first of all, it is high and stable quality. Luker can give a specific characteristic taste that stands out from the majority of your chocolate thanks to Colombian cocoa beans, and Cargill will give a classic high-level taste, as the company is a world leader in cocoa processing.

- Pay attention to the important trends of the current time: functional nutrition, healthy lifestyle, vegan products.

- Do not complicate production processes unnecessarily. Even a harmless ingredient that you just need to buy and just add as a sprinkle complicates the production process.

Step 3 — Create a financial model in which costs and revenues are visible

Once the business concept is defined, we create a financial model in which it is necessary to predict income and expenses. Most likely, in reality everything will be completely wrong, but at the stage of developing the model, you will already be able to check how realistic your model is in terms of business performance.

Step 4 — Search for premises and its arrangement

The minimum area to start such production is 100 square meters. 200 meters is a comfortable area to start, so to say with a margin. At 200 square meters there will be room for a warehouse and an office, where as 100 square meters will likely only have room for the production process.The more entry groups the room has, the better. Ideally, if there are 3 of them, you can ensure the entry and exit for personnel, the entry for ingredients and the exit for finished products from different doors, ensuring the principle of non-intersection of flows. Try to find the area that is most suitable for a quick start, as repair costs will increase the launch budget, which in turn prolongs payback periods. Moreover, if the equipment can be sold in case of failure, the repair expenditures can't return to you.

Advice:

Windows. Large panoramic windows in production rooms can be a problem, especially if they face south. Direct sunlight, falling on the product, heats it regardless of whether it is cold in the room or not. If you are interested in the room, and the windows are large, then you can glue them, for example, with foam material, in which one side is covered with a shiny film.

Waste. In our case, we lose not just fat, but cocoa butter, which becomes hard as a stone if it cools. In order to avoid problems, it is necessary to examine the horizontal waste water path from the connection point to the entry point to the the main water supply pipe with a cross section of at least 110 mm. If the main water supply pipe is longer than 3 meters or hidden under the screed, then this must be taken into account as a factor complicating the preparation of the room. Legislation prohibited to the companies to discharge wastewater containing oil without first cleaning them, so according to the rules you need to install a grease trap. Installing such a grease trap will save you from problems with a possible congestion of sewers, but it will create a new problem - cleaning the grease trap. Regular cleaning of the grease trap is necessary and, if it is in your washing room, then each time you clean it, you will have a “nuclear explosion” from the bacteria into the environment. Therefore, we recommend installing these grease traps outside the production room.

Electricity. This is an important parameter for evaluating a room and determines your production potential. Typically, production equipment is rated at 380 volts and collectively consumes a lot of energy. For an accurate calculation, it is necessary to summarize the power consumption of all electrical equipment and add 25% to the growth. We recommend considering rooms with a capacity of electric networks from 25 kW. It is also worth evaluating the condition and quality of the electrical wiring in the room. If it is of poor quality, then it is better to add it to the estimate for replacement.

Hot water. It is not very difficult and even the lack of hot water should not bother you. The problem can be solved with the help of a water boiler or a flow heater. We recommend using a boiler with a minimum volume of 100 liters.

Floor. Maximum load occurs on the floor, as chocolate will be constantly on the floor and more effort will be required to clean it. So, for example, metal spatulas will be used to remove chocolate from the floor, and this is an additional operational load. An ideal option would be flat concrete floors with a special coating. Such floors have no seams and are very durable to mechanical stresses, but they are quite expensive if you install them by yourself. Ceramic floors are also wear resistant, but joining seams will cause problems because during operation, chocolate, or rather cocoa butter from chocolate, will be mixed with dust and clogged in them. For high-quality cleaning of this floor you will require much more time and, as a result, money. As a budget option for flooring, you can use commercial linoleum with high protective characteristics. But bear in mind that the surface on which the linoleum is laid must be flat, otherwise linoleum breaks are inevitable in places of floor level differences. You can pay attention to the places where the walls are connected to the floor. In the case of linoleum, we recommend planting about 10 cm of linoleum on the wall, forming a radial transition. Also in the case of concrete floors, we recommend that such a radial transition be equipped with a cement mixture. Such a technological solution will provide ease of wet cleaning in these places.

Walls. Walls must be washable. Therefore, you can use ordinary washable paint, preferably oil in those places where chocolate is most likely to spill.

Ceiling. The ceiling must have a washable surface, so it can also be simply painted. However, it is often possible to find systems like Armstrong when a false ceiling of pressed fibrous materials is installed in a metal profile. Such ceiling systems have a low hygiene indicator, because the dust that accumulates above this ceiling falls into the product during vibrations from slamming doors or during replacement of lamps or wiring under such ceiling. We recommend to evaluate the possibility of dismantling such a ceiling in the rented room and simply paint the ceiling with washable paint.

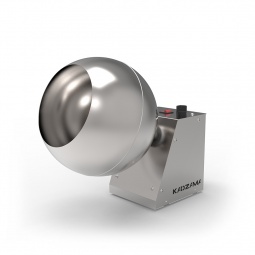

Ventilation and air conditioning. Forced-air and exhaust ventilation will provide a comfortable working environment and is especially necessary if you plan to produce powdered sugar to speed up grinding or stain molds with cocoa butter. In the production of powdered sugar, small particles of sugar fly in the air and enter the lungs, settling in them. They also create a fire hazard, as they conduct electricity and may cause a short circuit and fire. Air conditioning of such a room is a vital necessity, as the equipment emits heat and it is necessary to maintain a climate in the region of 22-23 degrees. Otherwise, the effectiveness of the equipment falls. Refrigerators won't cool as efficiently, and melangers have to be set at lower speeds to lower the mass heating temperature. We recommend using ducted air conditioners to cool the room, as the ability to dissolve the cold in special sleeves allows you to cool not only the room, but also bring it out to solve technical problems. For example, to cool the product in a panning drum or to cool the melanger.

Equipment:

Depending on the manufactured assortment of the planned output volume, the amount of equipment can vary significantly.

On the KADZAMA website we have Business page where you can find different combinations of equipment for different business needs.

Professional equipment needed for the production of grated cocoa:

Inventory:

Refrigerator

Storage racks

Desktop

High displacement microwave

Libra

Hair dryer

Blender

Mixer

Boat (this is a blender)

Induction Tiles

Freezer

Large containers

Small containers

Silicone spatula

Putty knife

Chocolate forks

Scrapers

Pallet

Whisk

Silicone mat

Large stewpan

Small stewpan

Sieve

Scissors

Pastry Bag Nozzles

Stationery knife

Confectionery paper

Disposable Bags

Transfer film

Silicone syringe

Latex gloves

Kandurin brush

Ribbons

Paper sockets

Packages

Scotch

Step 5 — Staff

«Hire slowly, fire quickly.»

You can start the production process with just four employees. With an increase in revenue and an increase in production capacity, it will be possible to expand the staff.

Technologist manager. A person should be well versed not only in the technological aspects of chocolate production, but also have a good understanding of how machines work and be able to tune them.

Chocolatier / packer. The task of the chocolatier / packer is to follow the clear instructions of the technologist, so trained confectioners are suitable for this work. As a rule, these are young people from 20 to 35 years old. You will require assiduous people. One casts and molds, and second one packs. These individuals should be interchangeable in case unforeseen circumstances occur.

Storekeeper / Purchaser. A person who is well versed in accounting programs and will be able to organize accounting, as well as be able to organize work with suppliers and ensure uninterrupted supply of the warehouse.

Seller. A good seller who immediately understands your product and starts selling is truly a rarity (and will probably be very expensive). Therefore, the role of the seller in the first stage, we recommend to be carried out by the owner, as this is the most important part of the business. No sales - no business.

Step 6 — Marketing and Sales Increase

- Well-planned and implemented advertising on the Internet;

- Exhibitions;

- Social networks. Nowhere without them today.

- Developing pages on facebook and instagram is now considered not even as a good manners rule, but an integral part of the business. Take the time to learn about good photography and smm rules. This competency is best left to yourself as a business owner, as only you know best about the values of your product, you are always in the store and at any moment ready to take a beautiful picture with your phone that you can describe very appetizingly. And besides, you have a small budget to cover this type of activity in expenses. It’s better to spend the money on a targetologist who will customize advertisements based on your posts and attract more audience to your pages. To try and understand the intricacies of the advertisement settings of ad campaigns is not really worth it and is quite difficult and time consuming. Remember that you should be focused on the product. When you describe and photograph it, it is part of the product. But the promotion of this content is a tool to increase coverage and it is better to hire a specialist.

- Hang out wherever you can, and talk about your product, give your product at all parties and become a sponsor of events. Give your product As much as possible so that it becomes an “news feed”, product will be mentioned and people will tell that you were at a party, and there were such sweets!

- Take part in holiday fairs. Set a goal to make money at the fair. The fact that this will add recognition to your store for granted. Fairs and exhibitions usually cost decent money and require effort to prepare and conduct. Therefore, you can participate at such events, just do not forget to set a goal to make such participation profitable for you.

Just a moment...

Just a moment...