Checklist for choosing a big melangeur for manufacturing chocolate and nut spreads.

Tags:

Checklist for choosing a big melangeur for manufacturing

For every craftsman sooner or later there comes a moment when the current conditions begin to crush. The home kitchen is getting cramped, and the beloved baby-melangeur can’t handle new orders. What do we have to do? Yep — move to the workshop and think about choosing a bigger melangeur. But here's the problem: there are so many! Which one to choose?

Yes, all melangeurs work the same way: they grind dry oil-containing ingredients into a homogeneous mass, replacing three units of factory equipment: pre-grinding, fine grinding and conching. As in the case with the choice of ATM, a person who doesn't understand the technical intricacies can easily buy expensive unnecessary options under the guise of revolutionary features.

We are a school of professional chocolatiers and have been teaching people how to make chocolate since 2010. During this time we worked with different melangeurs: both foreign-made and domestic. Today we’re taking all our melangeur experience and making the ultimate checklist for choosing the ONE & ONLY large melangeur which would perfectly fit your manufacture.

Let’s go!

Let's start our checklist with the main element of melangeur — stones. Why is this paragraph not called «millstones»? Because the stones in melangeurs are not only rolls, but also the base bottom of the bowl. The first thing you should pay attention to here is the density of the stones. The vast majority of melangeurs use granite as a material. It can be porous and dense. In no case do we recommend buying a melangeur with porous granite stones, because due to its loose structure, it tends to crumble and fall into the product. And since you want the consumer to enjoy chocolate and not visit the dentists, then it’s worth taking a melangeur with stones made of dense granite. In addition, it’s less prone to wear and such stones will have to be changed less often.

Is there a material denser than granite? Yes, quartzite. It is denser and therefore more difficult to process, which makes such stones more expensive. Is it worth it to overpay for quartzite? No, dense granite is enough.

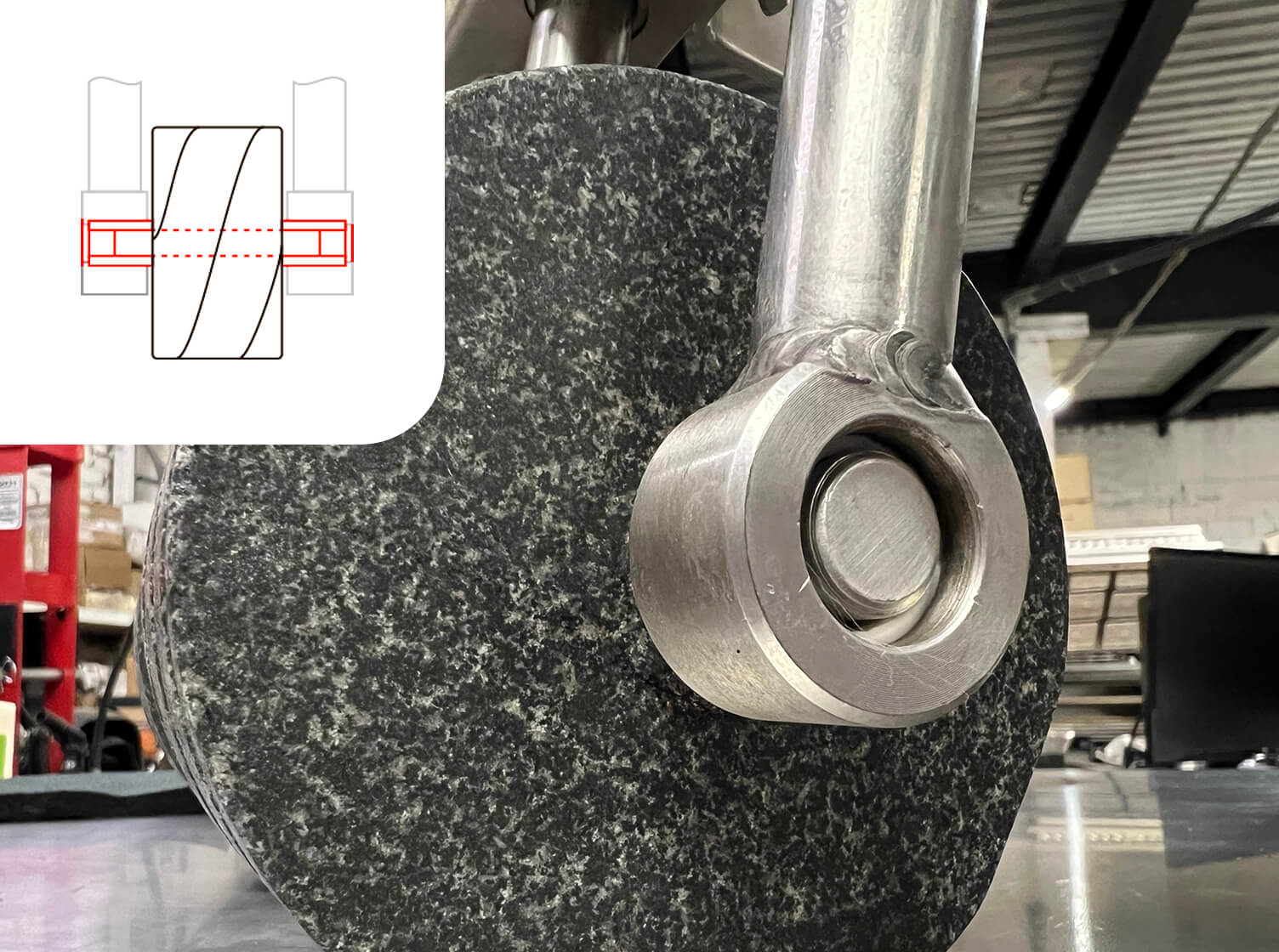

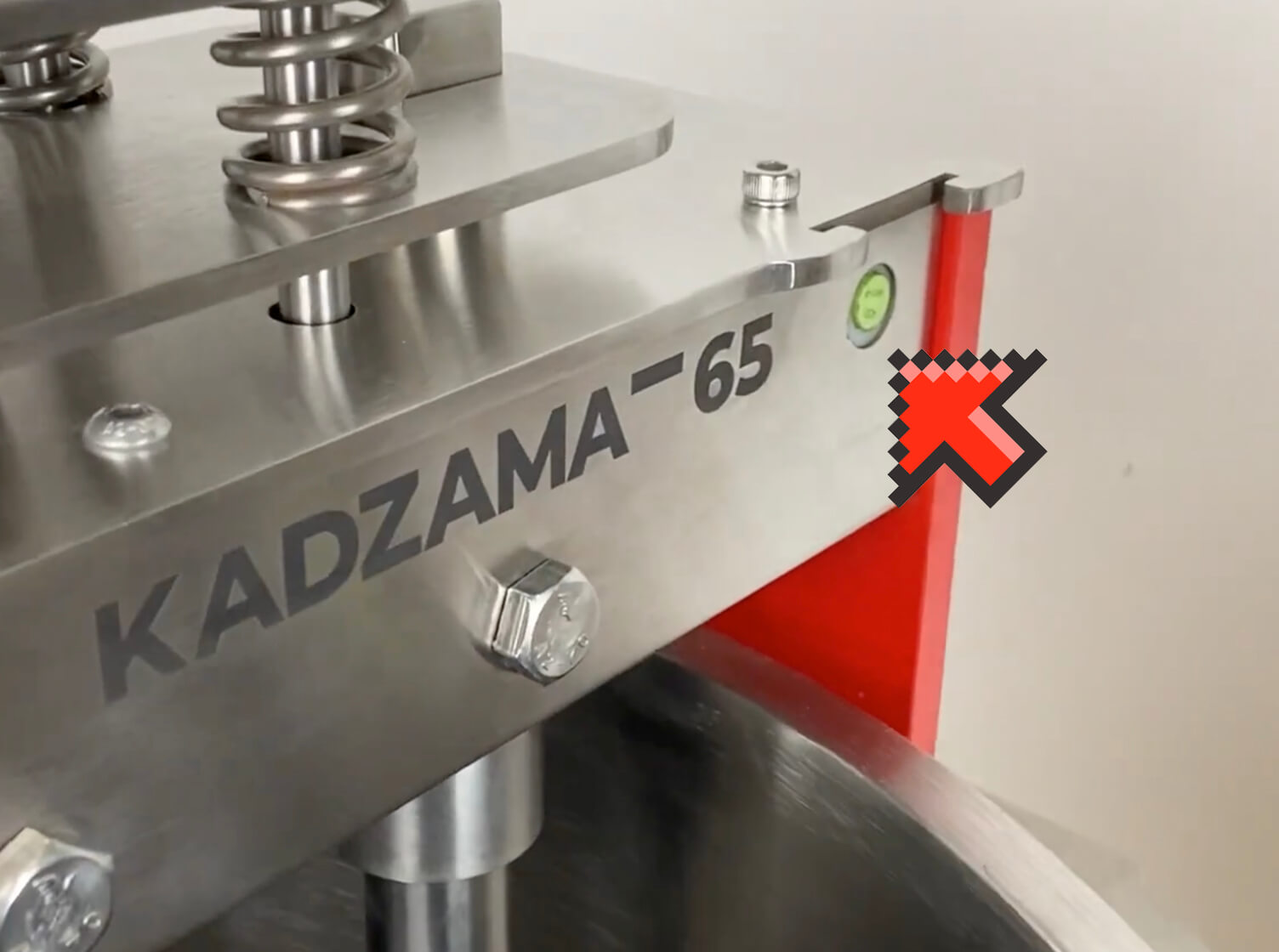

Moving on — a groove. It can be circular and spiral. Which groove to choose? If you’ve been following us for a long time, then you know that we recommend the spiral (or diagonal) groove. This type of groove creates a shifting contact spot between the stones, forcing the mass to tighten more intensively under the millstones, which gives a uniform and efficient grinding due to constant dynamics and a significant contact increase in the area of contact between the mass and stones. Melangeurs with such a groove are manufactured by KADZAMA and they have a patent for it. There are also melangeurs without a groove at all — old large «mammoths» for 200, 300 and even 500 kilograms. Due to the huge size of the stones and the slow speed of rotation, they don’t need to be grooved, because there is no wave effect.

Millstones with a spiral groove grind masses more efficiently than millstones with a circular groove. Learn more about spiral groove here.

While we haven’t gone too far from the groove, another important point that you should pay attention to is depth. Everything is simple here: the deeper the groove, the longer the work efficiency is maintained, and the update of the «tread» won’t be required soon.

As we said at the beginning of this paragraph, the bottom base is also stone, so keep our words about dense granite in your head. It’s also worth considering the moment of attaching the stone disk to the bottom of the bowl. Many manufacturers use epoxy for this. It securely fastens the entire structure together, but a small gap between the stone and the wall still remains. To avoid getting the mass into such a hard-to-reach place, we recommend choosing a melangeur in which the glue is additionally hidden under a silicone gasket.

The stones are done, now let's talk about how they spin. If you see that bearings are used in the melangeur, then the manufacturer clearly doesn’t think about the health of your consumers, because the bearing requires a grease that can seep into the product. Also, the bearing tends to collapse over time, which can lead to the ingress of its small elements into the mass. The best option is when the guides and axles of the stones move inside special bushings made of a wear-resistant anti-friction thermoplastic-based fusion (the melangeur from this review uses ZEDEX® material). The sleeve stands in the support rack, and is not mounted in the stone itself. In addition to safety for the product, this solution reduces the likelihood of jamming during operation, and also provides a quick and easy replacement in case of wear without specific skills and sending the equipment to a service center.

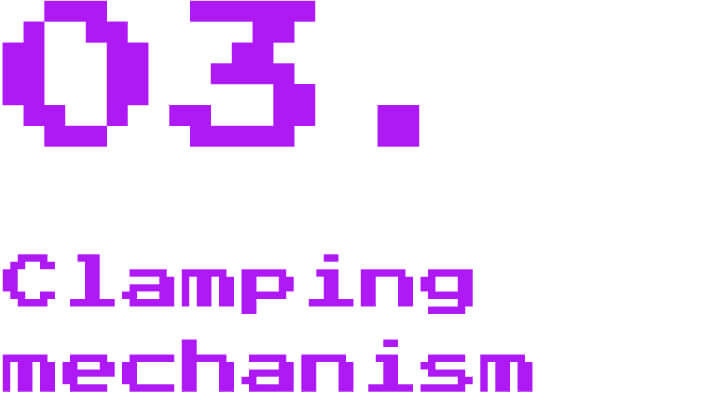

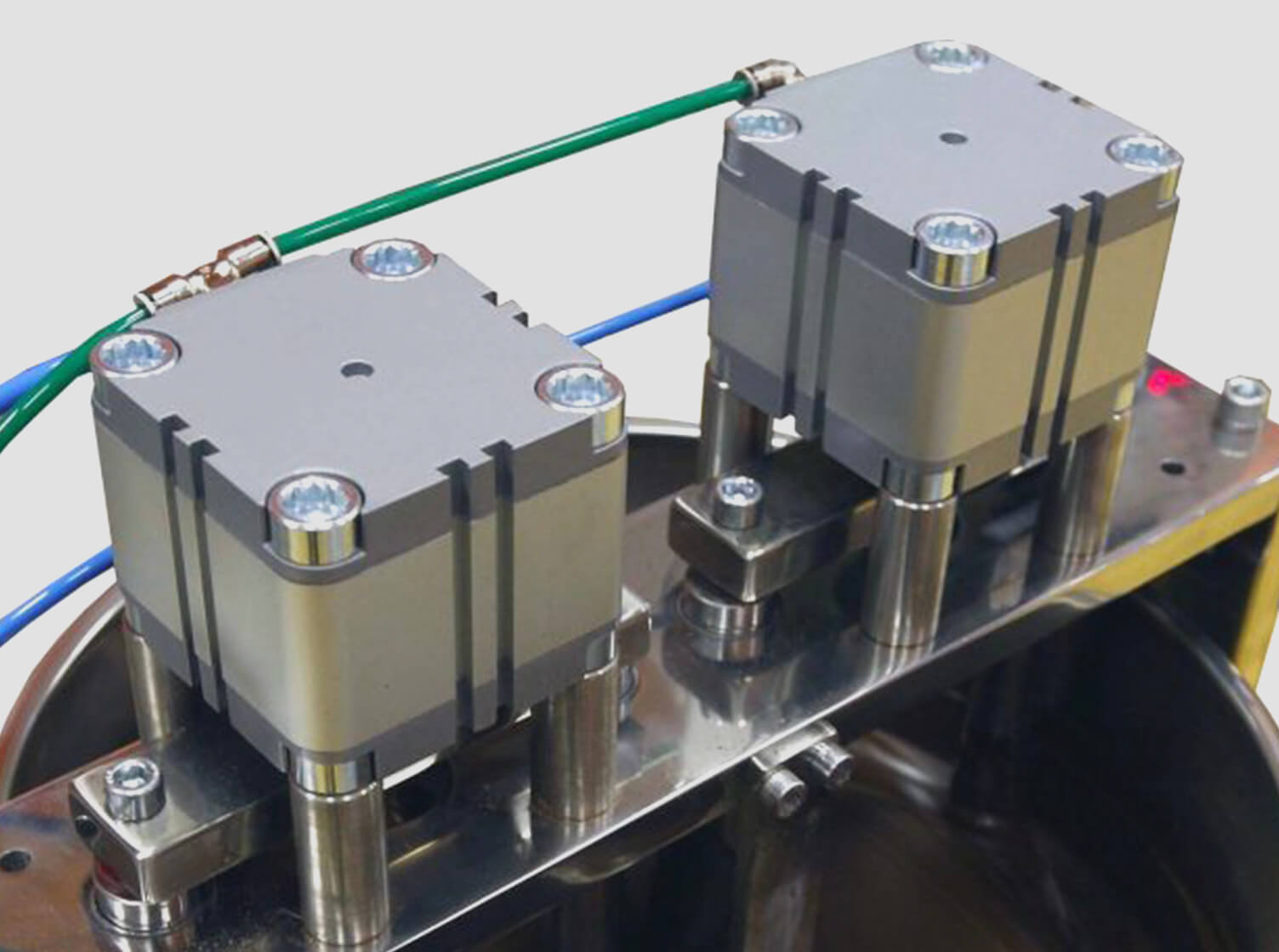

There are two types: spring and pneumatic. There is no difference for grinding, but the devil is in the details — pneumatics are much more expensive and require the compressed air supply, which entails the complication of the entire system: an additional unit that requires electricity, pipes sticking out of the melangeur and not the easiest maintenance. If the pneumatic is broken, then the melangeur will stand idle until you fix it, which is much longer than replacing the spring (and the new pneumatics is also several times more expensive than a new spring). Okay, you will say, that pneumatics are capable of creating pressure up to a ton. But why do you need it? Break through the bottom of the bowl? The spring is reliable, cheap and just as effective and its force is enough to provide the pressure you need.

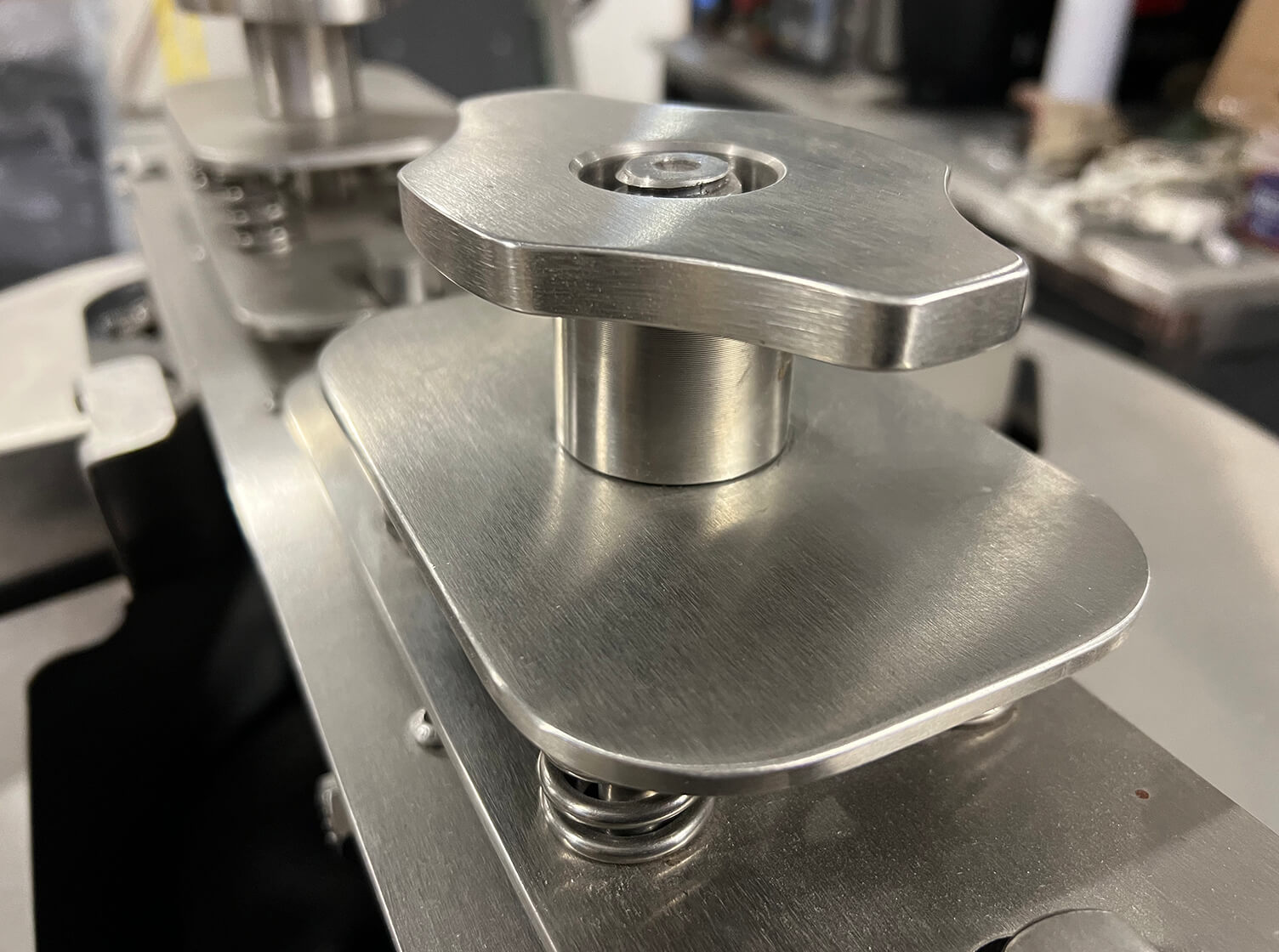

But there is also a nuance with springs that you should pay attention to: a wing nut or a clamping handle. We consider the wing nut not the best solution, since when tightened, it creates increased friction on the thread, which can lead to shedding of chips and getting them into the product. The clamping mechanism with handles allows you to relieve pressure from the springs, since at the moment of torsion along the thread there is no increase in clamping force: loosen the handle, twist it as much as necessary and fix it back.

Scrapers must be able to be removed. This facilitates the unloading of the mass and the washing of the melangeur. And here it’s important how exactly the scrapers are removed. If there is just a hole in the scrapers, then the small wing nut that fixes the scraper will have to be unscrewed to the end, which means there is a chance to drop it into chocolate or on the floor and lose it. We recommend choosing a melangeur which scrapers have a special groove. In this case, you just need to loosen the wing nut (you won’t be able to unscrew it completely because of the stopper) and remove the scraper. See demo below.

As a bonus to this point, we would like to note special pockets-brackets for scrapers. It’s really handy when you don’t have to first look for a place where to put the scrapers and then remember where it is.

Small, but important detail. Such an edge allows you to carefully unload the mass without dirtying the outer wall of the bowl. As in the case of a wine bottleneck: the drink is equally well poured with and without a rim, but without a rim the bottle will always be in wine. Chocolate flowing down the outer walls of the melangeur is not cool, not only because of the product loss, but also because of the need to wash the bowl from the greasy product that is difficult to clean.

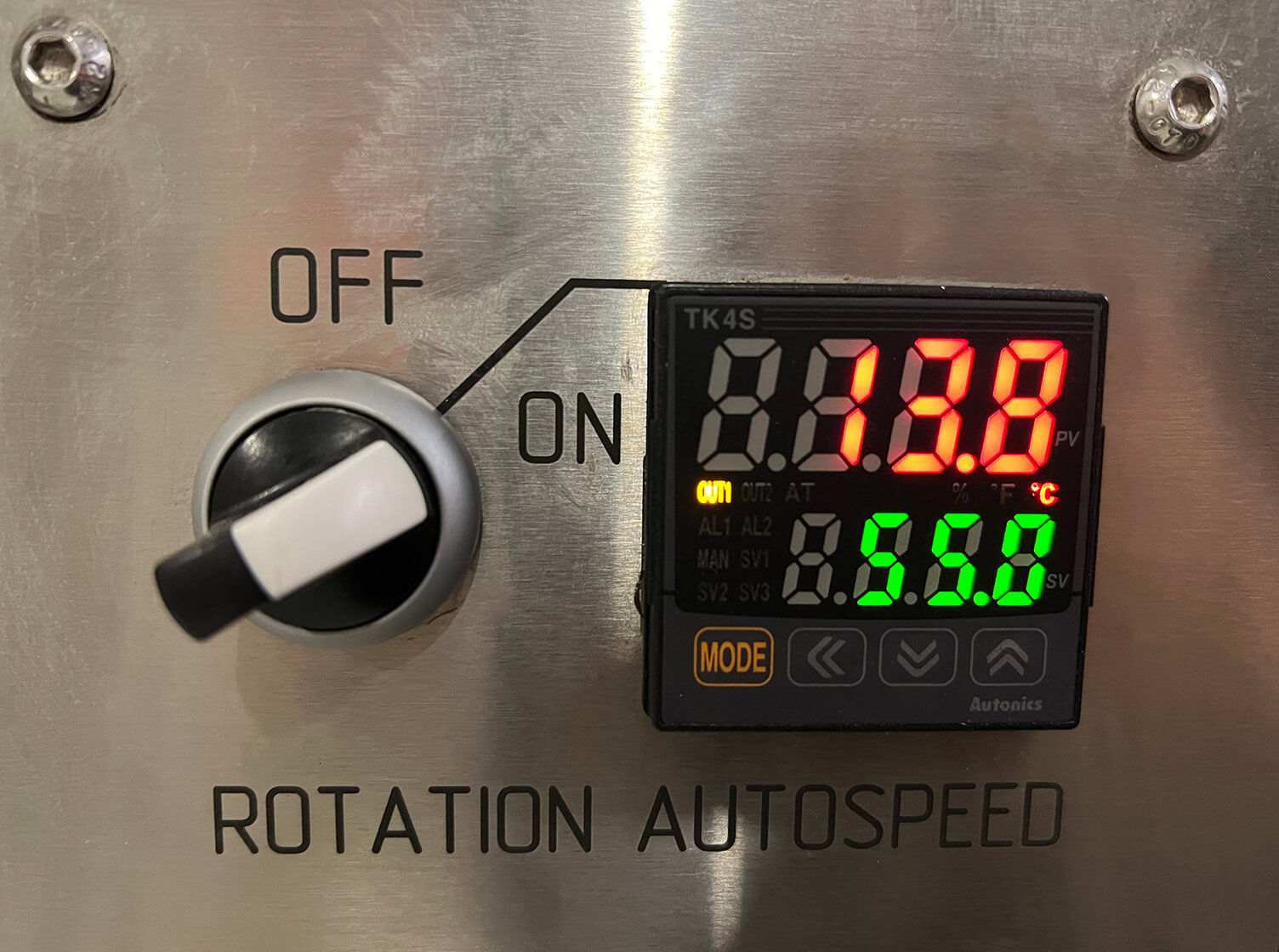

Moving on to smart features. Thermal controller is lit. It measures the product temperature with a probe and monitors the rotation speed — all this helps keep the temperature of the ground mass in a certain range specified by you and doesn’t allow it to overheat. This is cool for those who, for example, make products for raw foodists and vegans — it’s important for these guys that all ingredients retain their beneficial properties, that is, it does not undergo unwanted heat treatment. Grinding at low temperature doesn’t destroy vitamins and beneficial trace elements. Temperature control will also be a useful feature for those who want to experiment with the taste characteristics of their product, because chocolate that has been ground at different temperatures has a different taste.

The 85 kilo melangeur from our review has two additional sockets on the body, which allows you to connect any equipment you need without having to pull the extension cord and then stumble about its ubiquitous cable. You can easily connect a heat gun to warm up the mass, a fan to cool it, or a special vibrating sieve to clean chocolate from external elements accidentally got in during grinding or insufficiently small unground particles of beans.

From the non-obvious — you can put your smartphone on charge to the body of the melangeur and shoot a long beautiful time-lapse while making your chocolate.

We don’t think that any of the manufacturers neglects this, but it’s still necessary to take into account that all elements of the melangeur that contacts with the product are made of materials that comply with hygienic and toxicological standards in accordance with EU requirements. For example, the melangeur bowl from this review is made of AISI 304 stainless steel, which is widely used in the food industry.

Another point about security, but now yours. We recommend choosing a melangeur that has overcurrent protection. This is necessary, for example, if there is sharp jamming or something prevents the bowl from rotating. In this case, the frequency converter will automatically turn off the power due to the increase in current consumed by the motor. It’s also worth paying attention to the built-in circuit breaker and a residual current device. The circuit breaker will protect against a short circuit and the RCD will protect you from current leakage to the body of the melangeur. By the way, a good melangeur should not turn on itself after a failure, but wait for the operator to start it, because uncontrolled self-starting with a frozen mass can lead to jamming, engine overheating and breakdown with costly repairs. Now you know it!

There is another important point about safety — lid removal sensors. How does it work? Simple: remove the lid — the melangeur stops the rotation. Such a decision will save the fingers of an inexperienced employee. He will definitely thank you later.

As a bonus, it’s cool when it’s possible to change the position of the lid so that the melangeur works and you can add ingredients at the same time. Pay attention to this.

Reverse is a very useful feature that allows you to briefly change the bowl movement in the opposite direction. This is necessary in order to free the stones in the event of jamming. The effect is similar to the slippage of a car by rocking it back and forth.

The reverse function cannot be left ON and only works when the button is pressed. This function is patented and exclusive to KADZAMA melangeurs (at the time of release of this article — March 2023).

Melangeur should not only spin, but also make it possible to easily unload the finished mass from it.

In modern large melangeurs there are three ways to tilt: handle, gearbox and electric. The handle is not the most convenient option, since the bowl together with the chocolate mass weighs a lot and you will have to control the tilt with considerable effort, especially if we are talking about a large melangeur, for example, 85 kg. The electric solution is elegant and modern for sure — you press the button, everything tilts and locks itself. But by choosing it, you run the risk of being in an extremely unpleasant situation — in the event of a power outage, you will be left with a full melangeur, from which it won’t be possible to easily unload the mass, so you will have to look for sophisticated ways to empty the melangeur in an emergency so as not to scoop out the frozen mass later. Electric tilt is a whim that only looks cool and modern at first glance, but in an emergency these show-offs will play a cruel joke on you. KADZAMA, whose melanger is in our review today, for some time produced a 57 kg melangeur with an electric tilt drive. As a result, this decision had to be abandoned in favor of mechanics, since the gearbox is simpler and more reliable. This is the power of customer feedback.

We are also in favor of this decision with both hands. We also recommend you to take a closer look at melangeurs with a flywheel. Firstly, despite the huge weight of the bowl with the mass, thanks to the smooth ride and small tilt step, you can set the desired frame angle as accurately as possible. Even a baby can handle it. Secondly, in the event of a power outage, you just need to turn the flywheel, pour the mass into some container, wait for electricity to turn on and load everything back. And finally — mechanics means a simple and understandable scheme of repair and maintenance.

Oh, before we forget. In the case of a mechanical tilt, pay attention to a latch (stopper) on the flywheel. It won’t only protect you from accidentally turning the flywheel with your ass, but also prevent the bowl from tipping over on its own from micro-vibrations during work.

Well, everything is simple here: the wheels are needed in order to easily move the melangeur to any place you need. If you are a fan of frequent rearrangements in the workshop, then its presence will be an advantage for you. Also the best wheels have stoppers: it allows you to fix the equipment so that it doesn’t move.

The longer the warranty period the better. This is really obvious, so we can immediately move on to less obvious things — post-warranty service.

A good melangeur should be easily assembled and disassembled for maintenance on your own when the manufacturer's warranty obligations have ended. Good technical support of the manufacturer, in turn, should respond quickly, work efficiently and solve most of the issues remotely, understanding your problem by photo or video call and, if necessary, send you spare parts to fix the defect. For example, KADZAMA is a manufacturer of professional melangeurs, which, after the equipment warranty expiration, continues to support its customers and provide post-warranty service.

If you have a KADZAMA melangeur, then their service center specialists will help diagnose, identify a malfunction and suggest what and how to fix even remotely as soon as possible, any necessary part will be sent without customs delays. Moreover, some service manipulations, such as replacing the sliding bushings of the millstones, are described in detail in the demonstration videos-guides, guided by which the client himself will be able to disassemble the melangeur together with the production manager, replace detail and assemble the machine back. It’s convenient, it doesn’t require you to stop production for a long time, send a melangeur back to the manufacturer or invite a specialist to your place — that’s cool!

- The stones should be made of dense granite, have any groove, but better — spiral and deep, and the epoxy glue that fastens the bottom base to the bowl should be hidden under a silicone gasket;

- Bushings are safer for the product and easier to maintain than bearings. Ideally, they should be made of a special wear-resistant and anti-friction material;

- The spring clamping mechanism is simple and reliable, unlike expensive and complex pneumatics. The main thing is to give preference to the clamping handle, not the wing nut;

- The scrapers should be removed and not have a hole, but a groove for easy removal with a fixing nut with a stopper;

- The bowl edge will prevent the chance of dirtying the outer walls of the bowl when unloading the mass;

- A thermal controller will allow not only to forget about overheating of the mass, but also to experiment with the product, changing the taste and creating products for raw foodists and vegans;

- Additional sockets on the body — lit. No need to pull an extension cord;

- All elements of the melangeur that touches the product must be made of materials suitable for the food industry;

- A good melangeur will not start itself after a power outage, but will dutifully wait until the operator does it;

- Overcurrent protection, RCD and a circuit breaker will protect not only the equipment, but also you;

- Lid sensors will save the fingers of an inexperienced employee, since if the lid is removed, they will give the melangeur a command to stop moving;

- The reverse helps to release the stones when they are jammed;

- Wheels will make it easy to move the melangeur around the workshop, and the wheels stoppers will fix the equipment in space;

- Warranty is good, good post-warranty service is even better. Especially when the manufacturer speaks the same language with you and can solve problems remotely;

- A good melangeur is simply and clearly disassembled for diagnostics and repair, and then it’s just as simply and clearly assembled back.

Using our guide, it will be easier to choose a cool melangeur for manufacture. For convenience, we have made a special checklist, where we have duplicated the details described above in the form of a table. Download and scribble!

And if you liked the melangeur from this material, you can learn more about it here.

Checklist for choosing a big melangeur for manufacturing

Just a moment...

Just a moment...