Cooling tunnels for chocolate. What are they for and for whom?

Tags:

Yo! Have you seen our article about proper cooling? In that article we told you about the importance of crystallization in the manufacture of chocolate, because the presentable product’s look directly depends on this process. And we also talked a little about cooling tunnels there, but decided to better leave it for another article. Well, its time has come.

Today we will only talk about cooling tunnels: design, how it works and who needs them.

All you have to do is ride through the cooling tunnel with us, CJ!

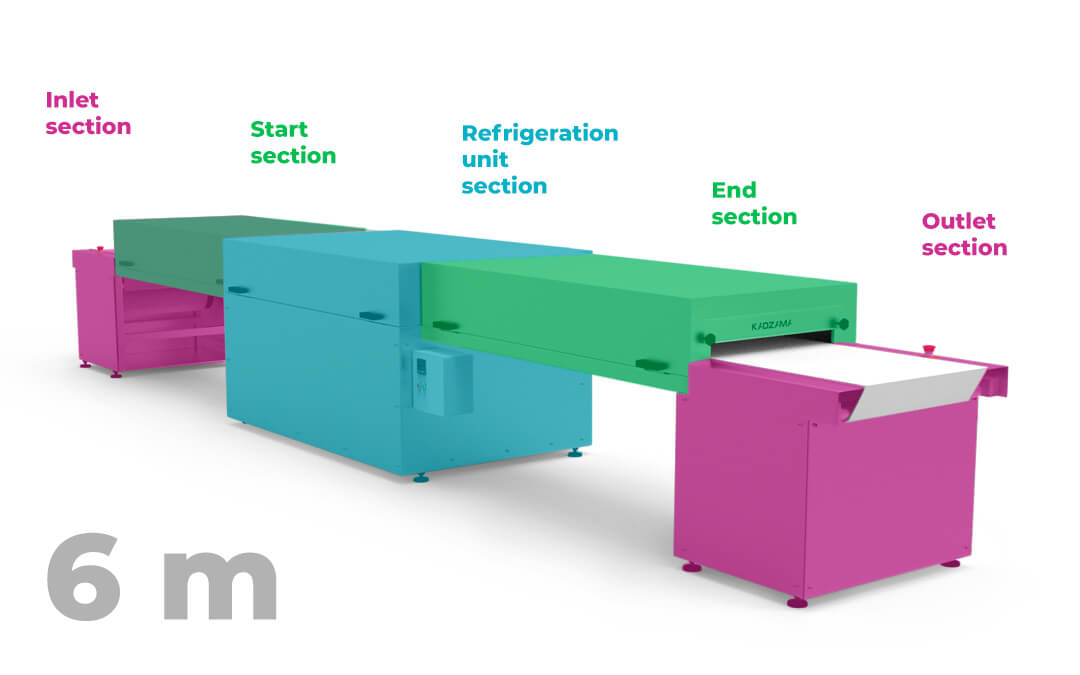

Cooling tunnel is a flow-through refrigerating chamber inside which products move on a conveyor belt. Despite various modifications of length and width, almost all cooling tunnels have an inlet and outlet section, a tunnel section (there may be a few), a section with a refrigeration unit (also may be more than one), a belt tension unit and a control panel.

To make it clearer, let's look at the design of the cooling tunnel in detail with the example o the basic model from KADZAMA 6 meters length.

The inlet section works as a conveyor — products are delivered to it for subsequent cooling (for example, from the chocolate enrobing machine). The output section has a drive unit — a motor, a gearbox and a gear. The belt is driven by a motor with a gearbox and a drum with a rubber coating (for better adhesion to the belt surface), on which a gear is mounted, rotated by the motor through the gearbox. The alignment of the tape occurs with the help of pneumatic cylinders, which are regulated by limit switches: when the belt shifts it presses on the limit switch and turns it on, the pneumatic cylinder shifts the direction of the belt and it goes a little to the side, and as soon as the belt stops pressing on the limit switch, it turns off, and the pneumatic cylinder returns to its original position.

Also the inlet and outlet sections are equipped with special adjustable dampers that go up and down depending on the height of the cooled products. This is necessary in order to reduce the loss of cold inside the tunnel. There is a special scraper at the belt exit for cleaning it from traces of confectionery.

The cooling chamber consists of regular pass-through tunnel sections and a cooling block — a separate tunnel section with a refrigeration unit and an air cooler. Air from the refrigeration section first enters the tunnel located under the belt and then exits from opposite sides through special openings into the main chambers where the belt moves and the cooling process takes place. Then the refrigeration unit takes away air and the cycle repeats again.

The top part of the cooling tunnel is completely removable for easy cleaning and when working in confined spaces.

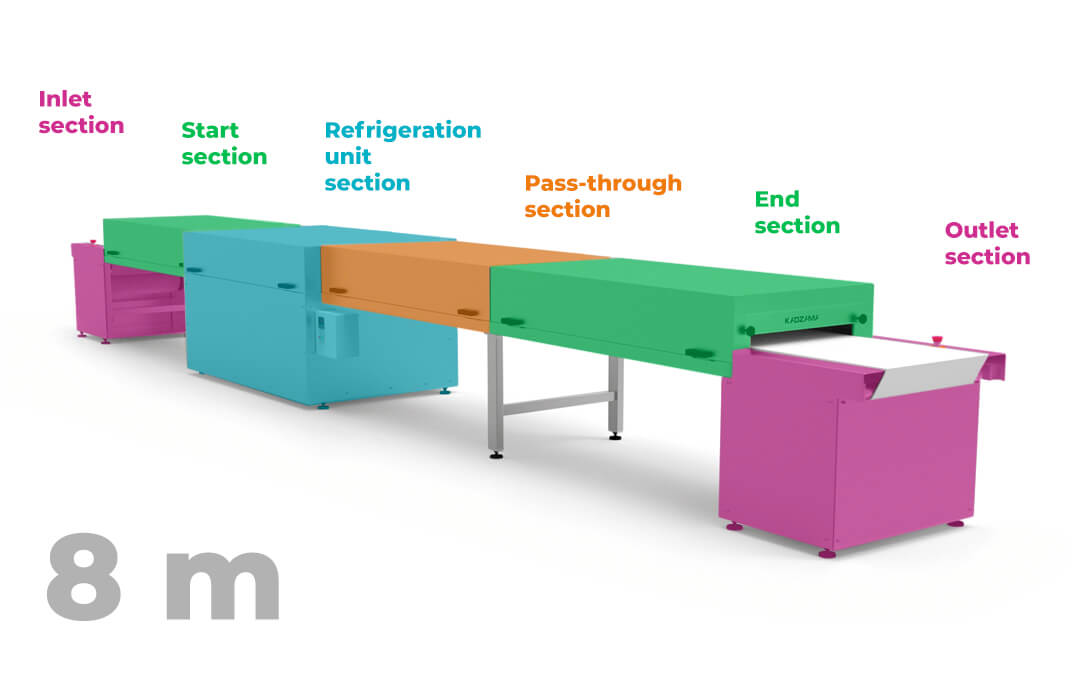

The presence of additional tunnel sections is due to an increase in productivity. For example, the KADZAMA cooling tunnel 8 m is per 2 meter pass-through section longer than the base model of 6 m. These two meters give an increase in productivity, since now the chocolate products need to travel an additional distance in the refrigerator, which means products must move faster in order to end up spending exactly the time necessary for proper crystallization in the cold. And the faster the belt moves, the faster the space for new products is freed up at the beginning of the tunnel.

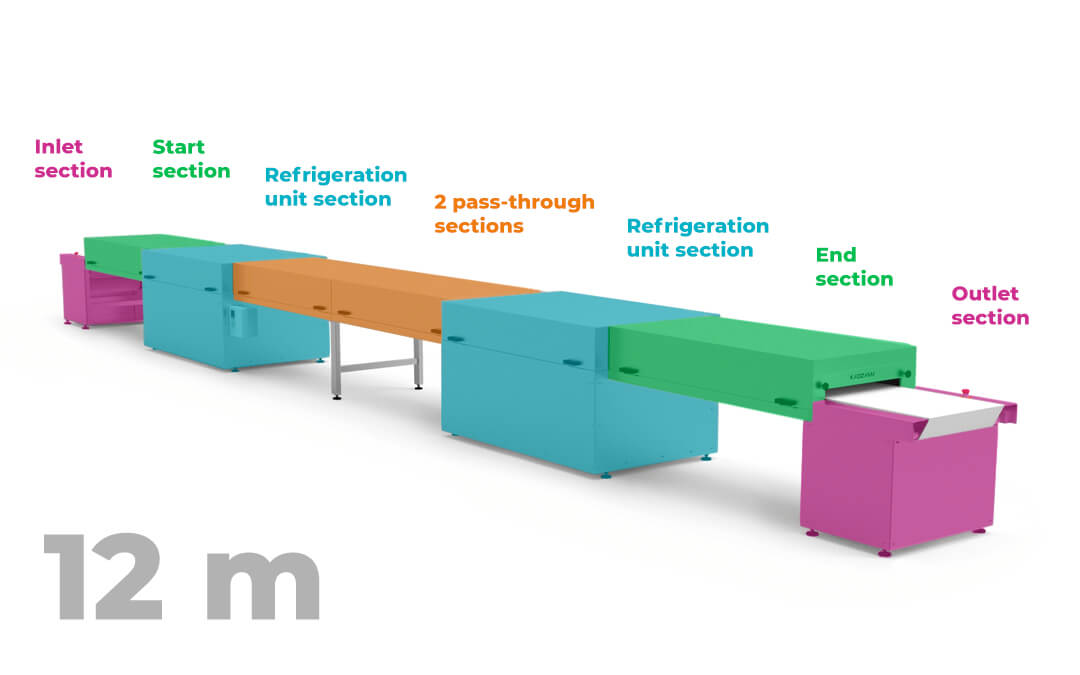

Remember we told you that there may be more than one refrigeration unit? The top model — KADZAMA cooling tunnel 12 m — has two refrigeration units. This allows you to create different temperature zones inside the tunnel, thereby setting a special temperature curve at which the temperature at the entrance will be slightly higher than the temperature at the exit, which will allow you to cool your chocolate products more gently and better.

It’s also important to note that the cooling tunnel is not a simple fridge you can plug into a power outlet and let it work. The cooling tunnel is a large and complex piece of equipment that requires installation and calibration. Usually, installation and commissioning is done by employees or authorized representatives of the company you purchased the tunnel from. Also the customer is obliged to timely supply power (380 V) and compressed air (you can buy a small compressor or allocate a line with compressed air) to the place where the tunnel will be located and work. Commissioning includes installation, testing and launching the equipment, adaptation of the technological process to the conditions of the customer's production, training and certification of personnel.

Unlike a regular fridge, the cooling of chocolate in the tunnel is a continuous flow and its efficiency is much higher. After hitting the inlet section’s conveyor belt, confectionery products covered with chocolate mass or something else (for example, marmalade) move at a set speed to isolated cooling sections, where they are blown with cold air. Inside the isolated space of refrigerating chambers, low air humidity is maintained, which leads to optimal crystallization of the chocolate mass. Thanks to the fan system and heat exchangers of a sufficiently powerful refrigeration unit, the temperature in the tunnel channel is maintained in the range from +2°C to +15°C. Belt speed and temperature are controlled by the control panel, which allows you to choose the right cooling conditions for different products with different thicknesses of the chocolate layer. When the chocolate masses are cooled in the tunnel, the second stage of the crystallization process is completed — the growth of cocoa butter crystals, which is very dependent on the time the products are in the cold.

Too difficult? Okay, in simple terms, we moved our products to the cooling tunnel and at the end we got perfect crystallization without stains and defects. But keep in mind that no one has canceled the «dew point» and the temperature difference between your room and the tunnel should also have to be taken into account. So without calibration and a couple of test cooling sessions no good will come.

And here you ask: «So perfect crystallization won’t magically happen the first time, then why do I need such a device at all?».

The answer is simple.

The tunnel is a great solution for those whose monthly output is close to a ton of chocolate. Making so much chocolate you can go crazy if you constantly transfer products to a tray, take it to the fridge, pull it out, pack it and repeat this chain of actions ad infinitum with your bare hands. In this mode it will be difficult for you to scale production if such a need arises.

In an hour via a regular fridge you can cool 100 standard chocolate bars weighing 100 grams each — that is only 10 kilos. So a ton of chocolate bars is 100 fridges. Insane!

With a cooling tunnel in place, all you or your employee will be doing is pouring chocolate bars and placing them on the tunnel belt. At the other end of the tunnel, products with correctly crystallized chocolate are accepted for packaging.

The tunnel can work 24/7, but make sure that the temperature in the room doesn’t exceed 22°C and there are no heat sources near the tunnel (stove or something like that).

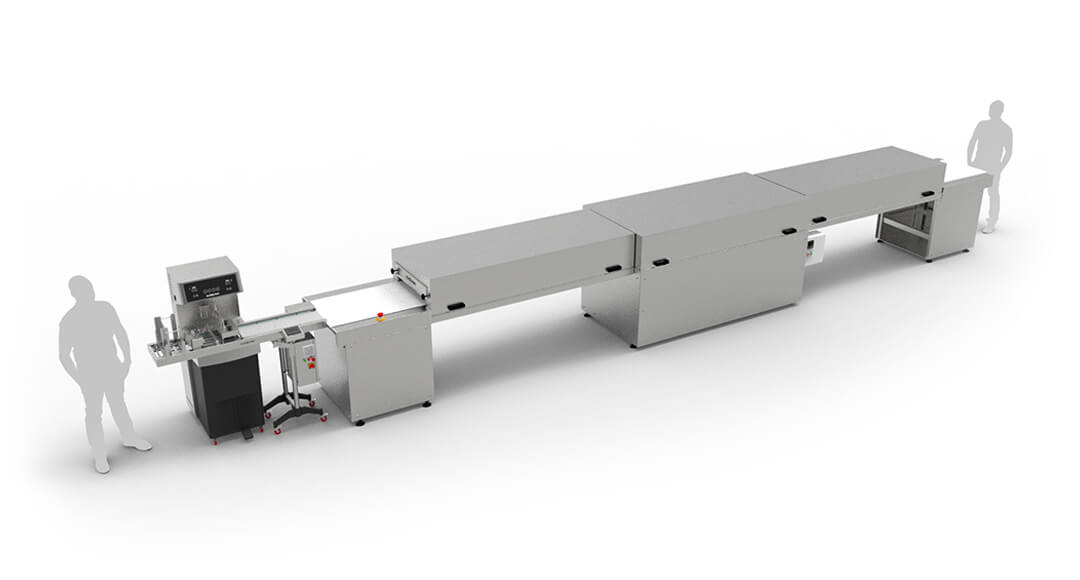

Well, if you produce not only bars, but also sweets and glazed products, then you will definitely like the cooling tunnel, because you are just one step away from almost complete production automation. Between the tunnel and the ATM, another device fits perfectly — a special chocolate enrobing machine designed to dock with the tunnel. Such a «holy trinity» will provide an almost seamless line, where, on the one hand, the operator lays out products for glazing or pours chocolate bars, and on the other, the finished product is accepted for packaging.

So what's the conclusion? The cooling tunnel is the best solution when it comes to cooling a lot of products at once without unnecessary manual operations, standardizing the high quality of chocolate crystallization and avoiding defects. And together with an ATM and a chocolate enrobing machine you get a mini-factory for the confectionery production

The cooling tunnel needs to be calibrated for each individual type of product and conditions in your workshop to achieve the ideal result, so it’s great for those already switched to large volumes of product and cannot scale normally without automation in this section of the production chain. If your production volume is less than a ton of chocolate products per month, then we don’t recommend buying a cooling tunnel, but continue to cool the chocolate in the good-old fridge.

Chill!

Just a moment...

Just a moment...