Tempering the nut spreads: why do you need it?

Tags:

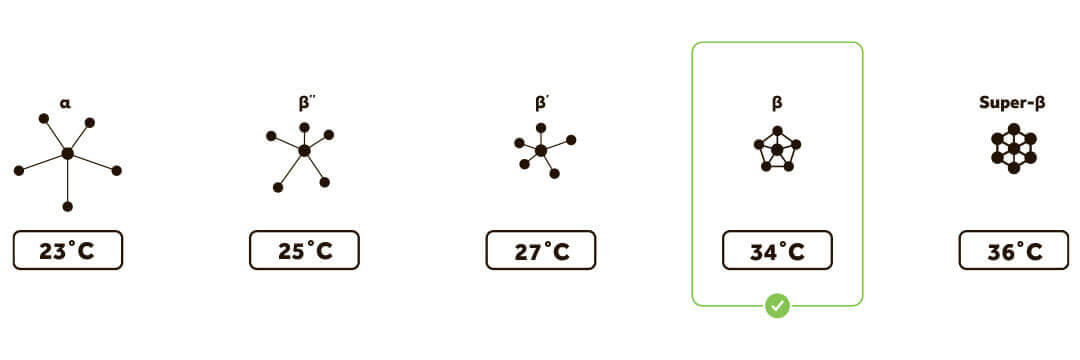

Chocolate needs to be tempered — everyone knows that. Well-pre-crystallized cocoa butter is in charge of a number of amazing chocolate characteristics such as gloss, nice texture and crunch at the break. Cocoa butter is the «philosophers' stone» of the chocolatier’s world and a special magic fat, which makes chocolate truly silky if handled correctly.

Chocolate is not the only product with cocoa butter, so the logical question is do all the products with cocoa butter have its special magic inside? Well, let's find out via the second most popular cocoa butter product — chocolate-nut spread (butter). If you're making spreads or about to start making it, but still don't understand why it's important to temper it too, then this article will change your life forever (or not).

Simple answer: tempering makes the spread’s structure more homogeneous and stable, such a paste splits much more slowly and retains the structure uniformity for a longer period.

But an easy answer is not enough, let’s go further.

What is splitting? This is when heavier particles (e.g. ground nuts, cocoa solids, sugar) fall down while lighter particles (fats) rise to the top. Have you seen a meat broth or yesterday soup that was just pulled out of the fridge? You can see some nasty frozen fat, which tightens everything with a crust. That is splitting. A rough, but a pretty clear example.

Tempered spread is less prone to splitting, maintaining smoothness and uniformity for a long time. The main difference from chocolate is that it contains enough stable cocoa butter that binds the dry ingredients, so they stay in a strict shape (bars, for example). Spreads have much less stable cocoa butter and it’s mixed with unstable liquid nut fats. Therefore, the spread remains soft and if slightly heated — fluid. If the spread is not tempered, then the cocoa butter simply doesn’t have enough strength to bind the ingredients and hold them — here comes splitting.

If the spread has splitted then, of course, it doesn’t look so great, but it’s still edible. In the case of urbech, if the expiration date hasn’t yet expired and the storage conditions haven’t been violated, it must simply be thoroughly mixed to restore uniformity. It’s more difficult with fatty spreads — in order to get a beautiful homogeneous structure, it must be heated, mixed and then tempered.

It makes sense tempering only spread with a sufficient amount of stable fat inside.

By the way, it makes sense to pre-crystallize (temper) only spreads that contain cocoa butter, because the idea of tempering is the formation of stable cocoa butter crystals (aka beta-crystals).

No cocoa butter — no crystals, so there is nothing to temper. If you try to temper a product without cocoa butter (or any stable fat, such as palm oil), for example, urbech, then it will be a waste of time and effort, because you won’t achieve any effect. It's kinda like trying to find a piece of meat in a vegan soup.

Spreads with different compositions can have several types of splitting. For example, urbech splits so that liquid fat floats right on its surface and fibers / other dry substances fall down and settle over time, so it becomes difficult to mix even with a spoon. But fans of natural urbech know about it and love it. It even works kinda like a naturalness indicator.

Okay, enough talking. Let’s have a look. Here are two jars of fatty spread.

Both jars contain the same chocolate-nut spread. The only difference is that the first has a tempered spread, while the second has untempered. See the differences? Hell yeah! Untempered pasta lost its marketable look. Its surface has some whitish spots and your tongue will feel grains, which melt in the mouth — these are randomly formed cocoa butter crystals that have different sizes and have no structure. Yep, lumps of fat.

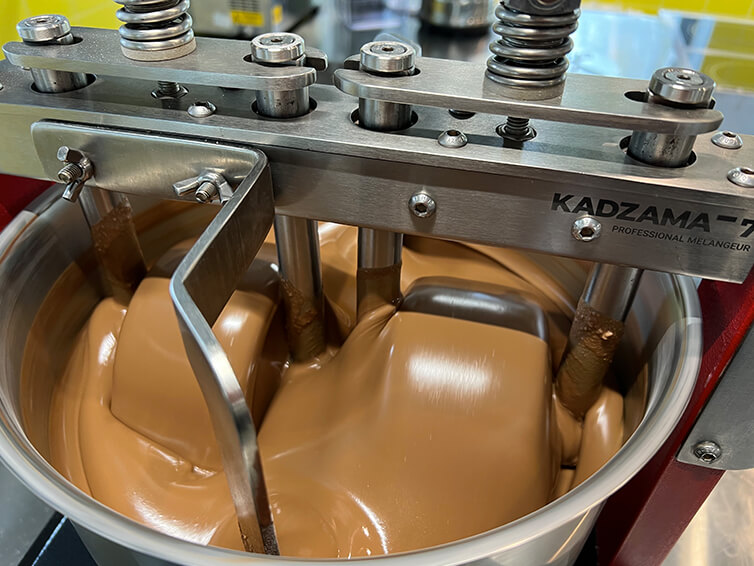

Why does the spread on the first picture look so cool? Due to correct pre-crystallization, a stable homogeneous crystal lattice was formed. The consistency of the spread turned out to be tender, smooth and uniform. The stable crystals have created the right grid that keeps all the ingredients in place. By the way, uniformity and silkiness are not only the achievement of tempering, but also of melangeur, which ground everything to the creamy state.

There are no special tips in the pre-crystallization of spreads: everything is like chocolate. Spread can be tempered on a granite surface with spatulas and palettes, but if there is a lot of spread, we recommend grabbing some additional equipment if you don’t want to go crazy.

Yes, but not all of them. There is an issue: in the melted state the mass of spread (rheology) is much thicker than the mass of chocolate, so some ATMs may take it as a problem and turn off due to the amperage limit setting on the motors (mixers and auger). When working with chocolate, the required amperage is approximately 1.2 amperes, if the mass is thicker, then obviously more amperage will be required, so the frequency converter will trace an increased consumption and stop the machine. This is necessary so as not to burn the motor and gearbox. At our lab we work with an ATM from KADZAMA, you can increase the amperage setpoint on it directly from the panel without any hassle and work with spreads (however, we highly recommend you to talk with the equipment manufacturer about what spread can be poured using ATM and what is not recommended, because spreads density can be different, depending on the recipe). Other machines we had couldn't do that.

Technical part is over, now — the process. We unload the finished spread from the melangeur into the ATM, press the button and wait. Everything is the same as chocolate: the ATM heats up the spread and pre-crystallizes everything in 15 minutes.

After the spread pre-crystallizes, you will need to set the desired dosage for the volume of your jar (or any other container) and press the button to fill it. This method is quite clean, because the spread doesn’t need to be poured into some kind of intermediate container and then filled with jars from it by eye or by weight — that saves a lot of time. Also remember that the «smart brains» of ATM replace the entire chain of processes experienced chocolatiers are engaged in, so any person without experience can achieve a high standard tempering quality on it.

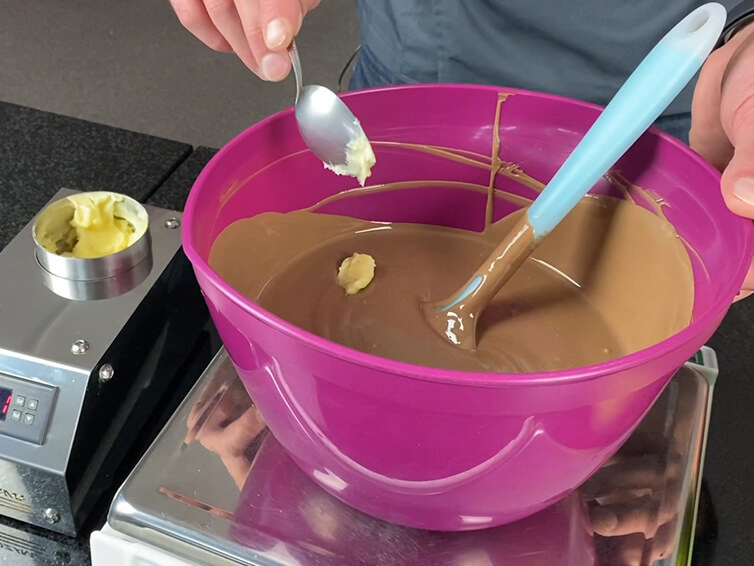

There are no special instructions here. Make cocoa butter silk, allow the spread to cool down and add a concentrate in the amount of 0.4% of the total mass. You can add «silk» directly to the melangeur (before adding, the spread should also be cooled, then add the concentrate of stable crystals, turn on the melangeur and mix the mass with the cocoa butter silk at low speed with no stones pressure, so the friction doesn’t increase the temperature, and stable crystals not decay) or you can add it into the container from which you’re going to pour the spread into jars — it’s up to you.

You can read our article about cocoa butter silk and the special incubator for it.

Regardless of the chosen tempering method the spread must be properly cooled after filling into jars. To do this, the jars of spread must first be sent to the fridge for 30 minutes (a quick crystallization process begins at a low temperature and spread solidifies). Then the spread can be left at room temperature for the final solidification.

Are there any issues? Sure! It’s extremely important to avoid large differences between the fridge temperature and the room temperature, so that condensation doesn’t appear in the jars.

Condensation is bad, because water, dissolving sugar on the surface, becomes syrup, and when it dries up, it leaves white spots that spoil all beauty and deprive even tempered pasta of its look. This is called sugar bloom.

But let's get back to our spread in jars, taking a closer look at it.

Let's start with an untempered one.

Firstly pay attention to the surface: whitish spots appeared. This looks ugly and may scare the consumer, because it creates a false impression that the spread is spoiled and the scarf is fungus.

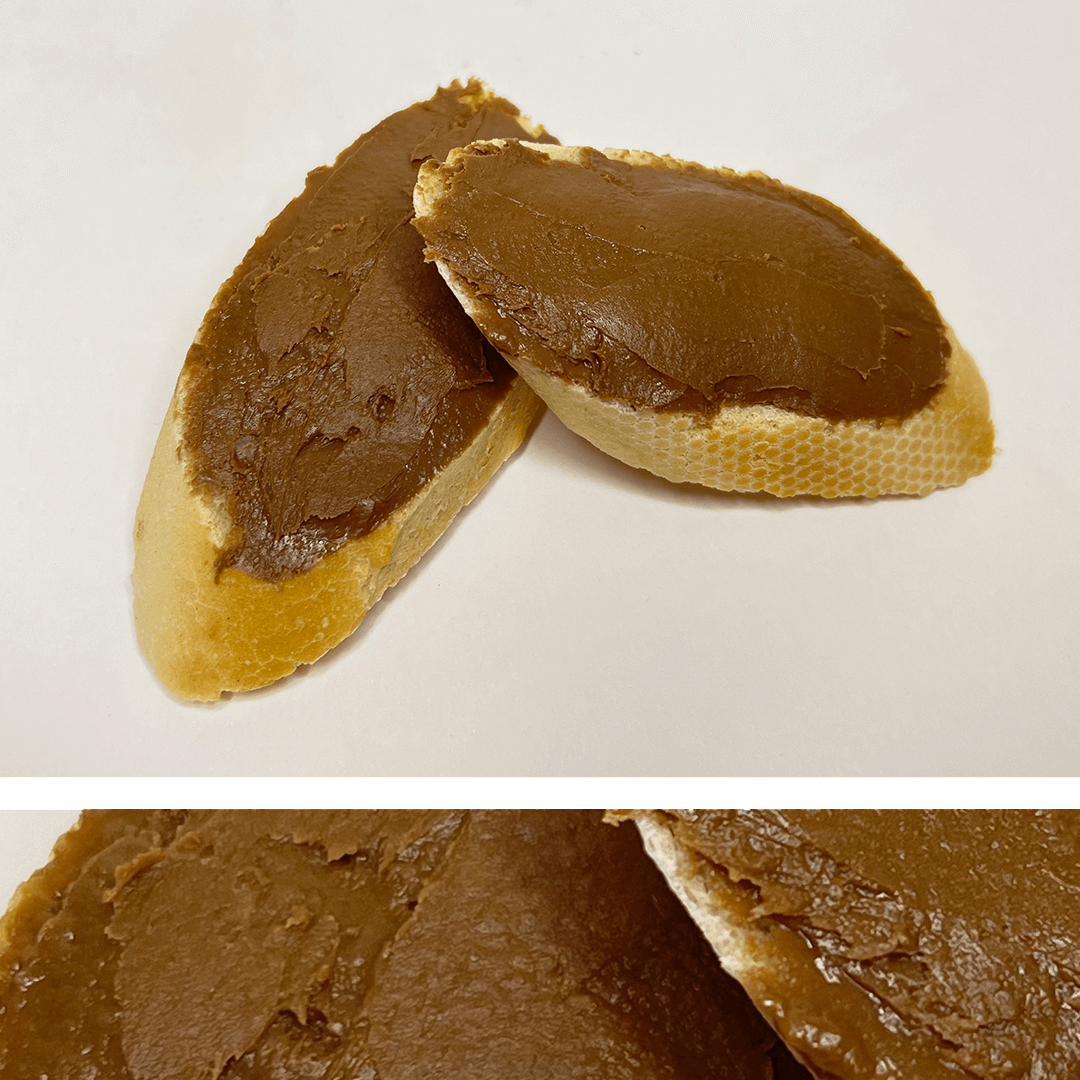

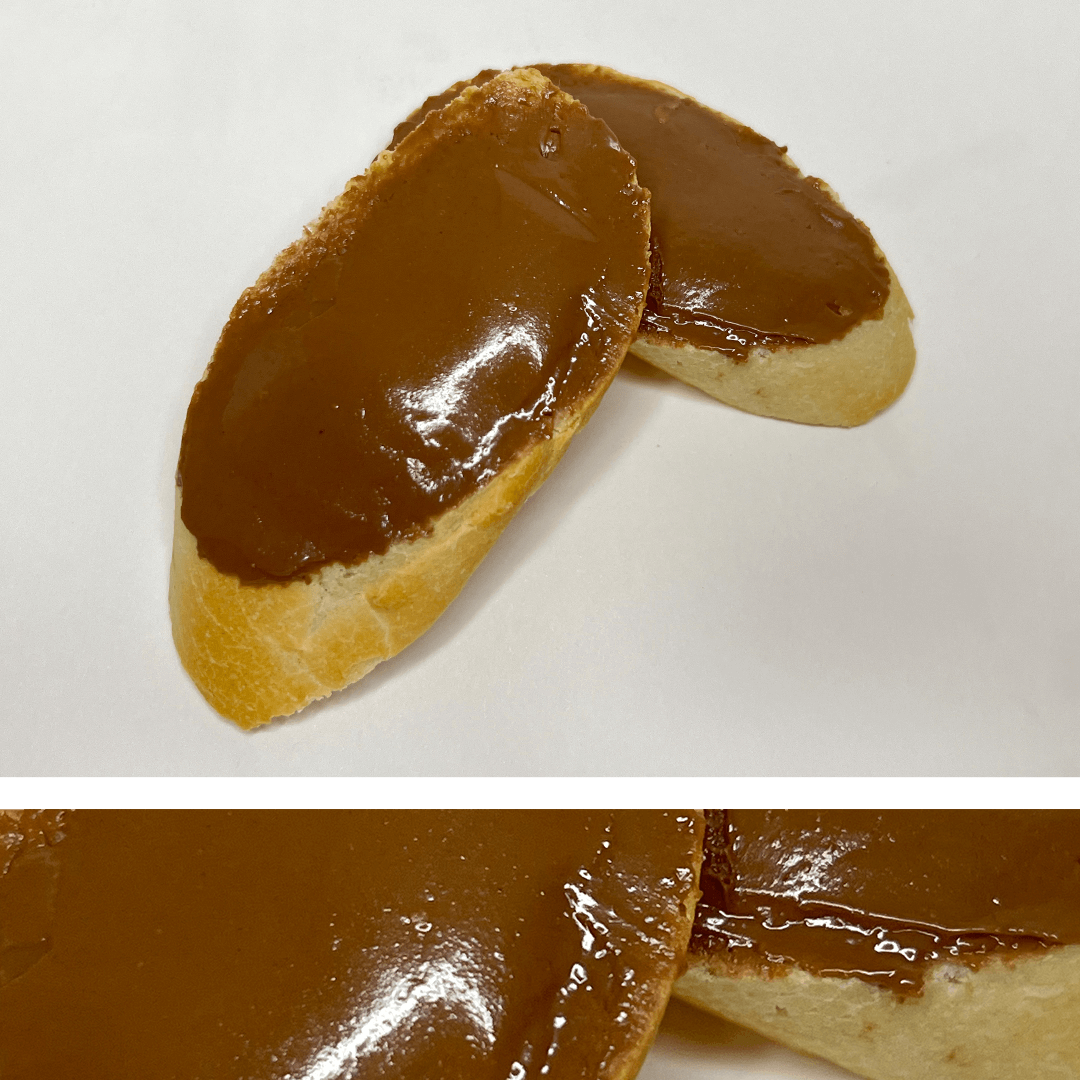

Grabbing some spread with a knife and putting it on a fresh baguette.

As you may have noticed, lumps are clearly visible on the surface of the spread — these are wrong, unevenly crystallized cocoa butter. Does it affect the spread taste? No, it tastes exactly the same. Texture is more about perception. Speaking of a «tasty» or «nasty» product, we also evaluate it from the organoleptics point of view. This means that we care about how we feel the taste, not how sweet it is or something else. Lumps of fat will immediately spoil the taste impression, because for the consumer it will seem strange, unground, unpleasant and rough.

Now let's take a look at a jar of tempered spread.

The first thing we want to note is that there are no white spots on top. We take a knife again and spread it on a baguette.

Perfect soft silky texture without lumps. And the taste…*crunch*...amazing.

Tempered spread retains its marketable look longer, has a delicate silky uniform texture and delights customers with amazing taste right to the very last spoon. Chocolate spread can be pre-crystallized in any way that suits you, but if you are a business person and looking for ways to standardize product quality and reduce costs (including personnel costs) then you definitely need some additional equipment.

It’s possible to use an automatic tempering machine for working with nut butters and spreads, but be sure to check if the machine is designed for such loads with the manufacturer. If yes — then you have a precious opportunity to automate your production and reach new volumes! At the same time, you don’t have to hire highly qualified personnel.

If you are not planning to build a small factory yet, then tempering with cocoa butter silk, which is made in the incubator for cocoa butter crystals, will help you to simplify spreads production. It's clean. It's fast!

Cheerio!

Just a moment...

Just a moment...