Why is it important to cool chocolate properly?

Tags:

Chocolate is a cranky lad that requires special handling at all the work stages: from careful sorting of raw materials to packaging. If it seems to you, that now you are 100% ready for absolutely all the hardest things after reading our articles about tempering, then we hasten to «glad» you — nope.

While making chocolate bars and figures our main goal is to make them look perfect: smooth, shiny, no muddy spots or streaks on the surface and signs of deformation. To achieve this ideal, chocolate needs to crystallize correctly at the very end of the production chain. So today let's talk about what is right / wrong crystallization, and how not to screw up at this important stage.

Crystallization is the process by which solid forms, where the atoms or molecules are highly organized into a structure known as a crystal. After pre-crystallization and pouring of chocolate into molds, it must be placed in a cold environment for complete cooling and solidification. Yes, chocolate will harden even without cold just at room temperature, but it won’t crystallize properly. Proper crystallization = proper cooling. This process is no less important than proper pre-crystallization, because the result and the appetizing look of the product also depend on it.

So for greater clarity let's find out ...

Nothing good at all. The bar can become covered with condensation, stains, streaks and even deform, but first things first.

Let's start with the condensate. It forms on the chocolate bar surface due to the huge temperature difference between the fridge and the room.

Condensation on the chocolate surface is not quite ordinary water — it’s sugar syrup. How did it happen? Sugar attracted water, dissolved in it, and syrup was obtained. After some time the water will evaporate, and the sugar will again crystallize on the surface in the form of white stains. This chocolate disease is called «sugar bloom», and to avoid it you first need to understand another term — «dew point».

The dew point is the temperature to which air must be cooled to become saturated with water vapor. This value changes due to two parameters: temperature and relative humidity. If during the cooling of the chocolate bar the temperature difference is too big, then condensation will form on its surface after you take the bar out of the fridge.

To calculate the dew point you need to know the temperature and relative humidity of the air in your room. The temperature will be shown by an ordinary thermometer, and to measure the air humidity you will need a hygrometer. There is also a 2 in 1 solution — psychrometric hygrometer.

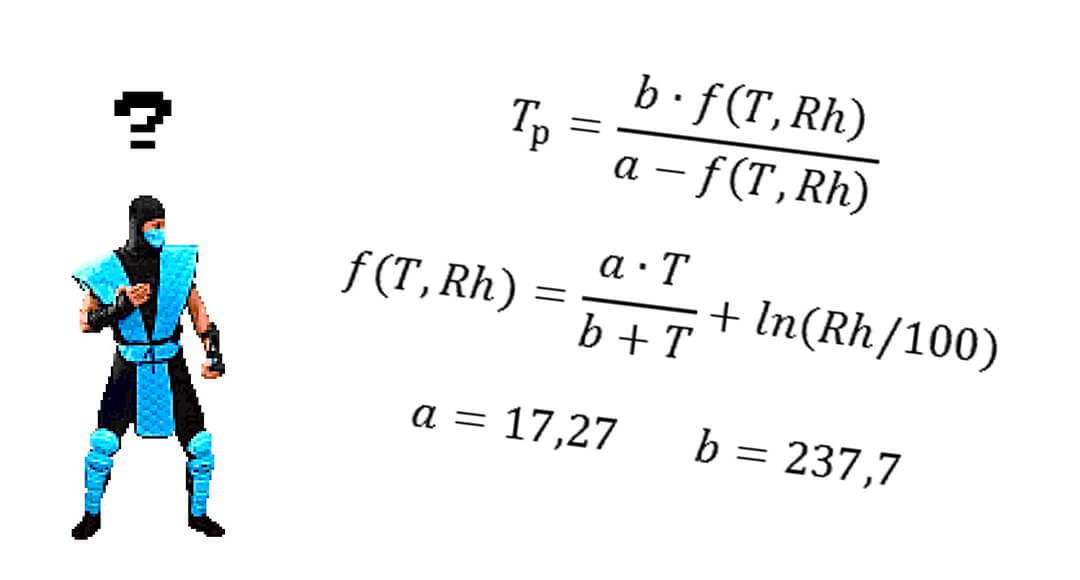

After measurements the obtained data can be compared with a special table, but as experienced chocolatiers we recommend using an online calculator. For all the hardcore lovers there is a good old math formula:

And for the super-geeks — thermal imager with built-in dew point calculation function.

Moving on. Surely you’ve come across a situation where chocolate is well pre-crystallized, temperatures are adjusted as it should and molds are prepared, but cloudy spots or stains still appear on the surface of a bar or figure — this is nothing more than a pattern of crystals that appears if crystallization is too slow or too fast.

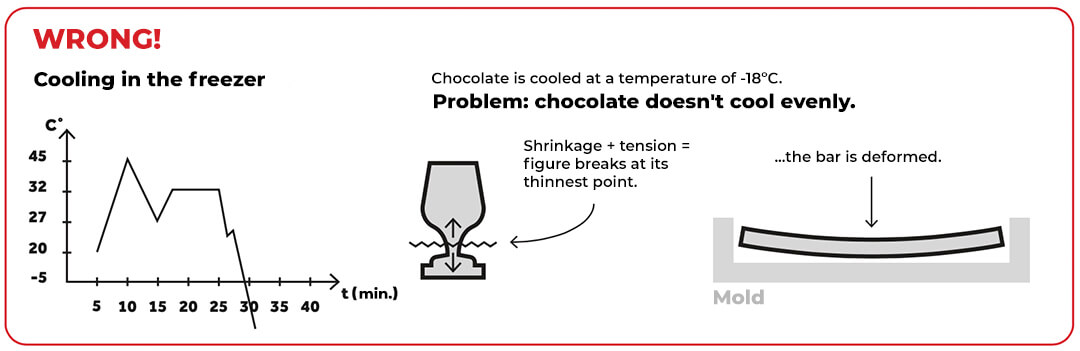

Too fast crystallization, by the way, can even lead to the bar deformation — it will bend up from the edges like a boat due to shrinkage during crystallization, which occurs at too low cooling temperature, regardless of whether your mold is: plastic or polycarbonate.

When you have come a long way to the finished chocolate bar, running into trouble during a seemingly easy task like cooling is incredibly frustrating. Luckily…

To avoid condensation and subsequent chocolate bloom you need to adjust the temperature difference between your room and the fridge. Ideal indoor conditions are a temperature of 18-22ºC with a relative humidity of 65 (+−) 5%. The temperature in the fridge should be 10 (+−) 2ºC, so the allowable difference will be 10ºC. It’s also necessary to control the chocolate cooling time. It averages 15 minutes, but we still recommend running a few cooling test sessions to calibrate the process and learn your conditions.

The next important point — do not rush to put the chocolate in the fridge immediately after pouring it into the molds, because at this stage its temperature is approximately 30ºC (the working temperature of chocolate), so the temp-drop will be too big and can lead to stains. Let the bar rest at room temperature for 3 minutes and a beautiful result is guaranteed.

Obviously, a cold pit, an igloo snow hut or the heart of your former love interest won't work, because it’s better to cool chocolate in a place where the temperature can be controlled, low humidity and no extraneous odors. So we have only two options left — a fridge and a cooling tunnel.

Fridges can be standard household (as you have at home, if you don’t live in a yurt) and professional. A household fridge is not suitable for working with chocolate due to the static type of cooling — the air doesn’t circulate, so the cold is distributed unevenly inside. Also static type of cooling is called drip or gravity: during work, freezing and thawing processes happen several times a day, which can increase the humidity level in the fridge.

A professional fridge has a dynamic (ventilated) type of cooling — forced air circulation via installed fans. The advantage of a professional fridge is the uniformity of cooling, which helps to maintain a stable temperature and a low humidity level, and a uniform cold distribution throughout the cooling chamber, which avoids the stagnation of odors — very useful in the case of chocolate, because during cooling no extraneous odors must be nearby.

The disadvantage of working with a fridge is the possibility to cool chocolate only in batches of the volume that the fridge can hold at once. If you make a lot of bars, this becomes a problem, because you have to wait until one batch cools down, then take it out and put another in the fridge. Wasting a lot of time, effort and money.

So this is where special cooling tunnels come to the rescue. It makes no sense to compare their performance with fridges, since chocolate is cooled by a continuous conveyor flow: from one end of the tunnel the product is laid out on a belt, and from the other it’s taken cooled and ready for packaging.

There are a few advantages of this cooling approach. No need to wait 3 minutes until chocolate cools down at room temperature. This is because the temperature at the beginning of the tunnel correlates with the temperature in the room. Refrigerated product volume and cooling continuity are related parameters in the case of tunnels. It’s no longer necessary to wait until one batch cools down to cool the other. All that is required is to lay the bars on the tunnel tape one by one as they are poured. There are also special enrobing machines that pair with cooling tunnels, making production more continuous and automated.

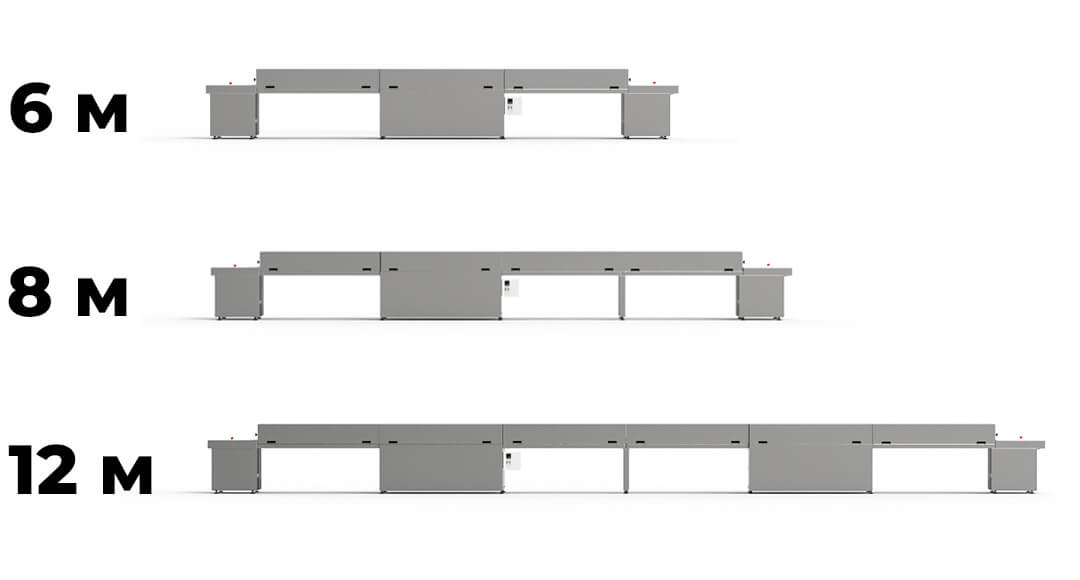

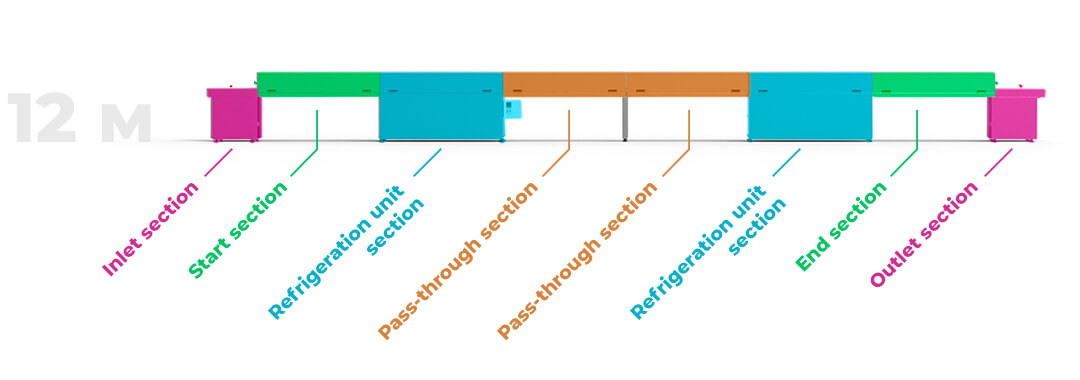

For example, KADZAMA produces tunnels in three sizes: 6 meters, 8 meters and 12 meters long. They differ in the number of sections. 6 meters is the minimum possible combination, consisting of two pass-through sections and one refrigeration unit section. 8 meters adds one pass-through section. And 12 meters has another additional pass-through section and another refrigeration unit section.

The longer the tunnel — the more productive it is. And having several refrigeration units inside will allow you to set different temperature conditions in different tunnel sections, but we’ll talk about this another time.

As you already understood, the cooling process is not so confusing in practice. All that is required is to monitor the temperature between the fridge and the room, take into account the dew point and let the chocolate cool at room temperature. This small set of rules will save you from such unpleasant surprises as sugar bloom, stains and product deformation.

Fridge (professional, of course) remains a universal way to cool chocolate bars and figures following all the rules. With a cooling tunnel, of course, there is less trouble, but acquiring such an expensive device just for the sake of proper crystallization is pointless, because its main advantage is cooling large volumes of products and automating processes.

Just a moment...

Just a moment...