What affects the shelf life of craft candies?

Tags:

Expiration date is a hot topic in the production of chocolate sweets. How long can candy be stored? How to preserve the taste, shape, texture, proper microbiology and slow down a plenty of chemical processes that reduce the quality of sweets during storage are the main problems that will always face the chocolatier.

Why?

Mistakes are costly. Finding good flavor combinations, market research, target audience research, advertising campaigns — all this will be a waste of time if your loyal customer finds a fungus after biting a truffle. And there can be many reasons for its sudden appearance.

The expiration dates of candies depend not only on the certain ingredients ratio in the recipe, but also on the manufacturing technology, compliance with sanitary and hygienic standards and rules in the workshop, regardless of the scale of your production, whether it is a large factory or home cooking.

The bad news is that we do not give clear formulas that will help you accurately calculate the shelf life for any recipe in this material — such formulas simply do not exist. The good news is that some things can be measured and planned. Therefore, today we will talk about what data helps to predict expiration dates, what factors lead to sweets spoilage and how you can reduce or completely avoid their influence.

Let's start horror stories with microbiological spoilage — the most basic and most dangerous factor for the human body, which can be accompanied by the formation of toxins and the development of pathogenic bacteria. Favorable conditions for the development of bacteria, fungus and yeast are water, air, a comfortable temperature and a source of nutrition. In our case — the candy itself.

The most obvious sign that the candy has gone bad is mildew. Many mistakenly believe that if the truffle is not covered with mold, then you should not worry, and everything is good with it. And there are even more desperate optimists who simply cut off a piece covered with fungus and think that from now on the product is safe. Unfortunately, such optimism can lead to poisoning, since the mold lives not only on the surface, but also penetrates into the product.

Violation of microbiology is not always accompanied by signs visible to the eye. In addition to microbiological spoilage, there are a number of other degradation processes that are invisible. For example, chemical processes are different types of oxidation more associated with fats. Outwardly, such damage, as a rule, doesn’t show itself in any way, but you can feel a rancid or simply unpleasant aftertaste that is not characteristic of the product. Surely there are not so many of you who are ready to give a second chance to nut butter or a rancid nut-flavored chocolate bar. You won’t go to the FDA with a complaint, but obviously you won’t buy the products from such a manufacturer anymore.

Spoilage can also occur as a result of a number of physical influences: mechanical damage, deformation or loss of integrity. Sounds harmless compared to the types of spoilage described above, but it’s important to note that physical processes can lead to chemical or microbiological processes easily and without warning.

BTW deformation is not always the result of mechanical damage — the candy can also be deformed as a result of drying out. Wet fillings tend to dry out, due to which its consistency begins to change, grains of sugar appear, it loses its silkiness, becomes rough and the candy changes appearance itself. In this case, voids appear between the filling and the layer of chocolate, which create excellent conditions for the growth of microorganisms — the «elements» mentioned above: air, temperature and water. The influence of air can be reduced by glazing the filling in chocolate, which will serve as a protective layer for it (which is why it’s important that the layer is intact, without cracks and holes). At the same time, the filling itself should also be inside without air bubbles, which can form when whipping ganache with a blender. This can be avoided by keeping the blender immersed in the mass while whipping. Of course, the most reliable protection against air is a vacuum, but let's face it: few people will vacuum candy after opening the package, so it's better to proceed from reality and protect the product in other ways. The temperature is even easier — it needs to be lowered, ideally, by storing sweets in the refrigerator so as not to allow microorganisms to feel good and grow quickly. But what about the last «element»? Let's figure out...

Yep, unfortunately, the presence of water in the filling composition is the main factor that significantly reduces the shelf life of the candy. Therefore, emulsion fillings spoil the fastest, that is, our dearly beloved ganache on cream, fruit puree, juice or just water. And the more water, the shorter the shelf life.

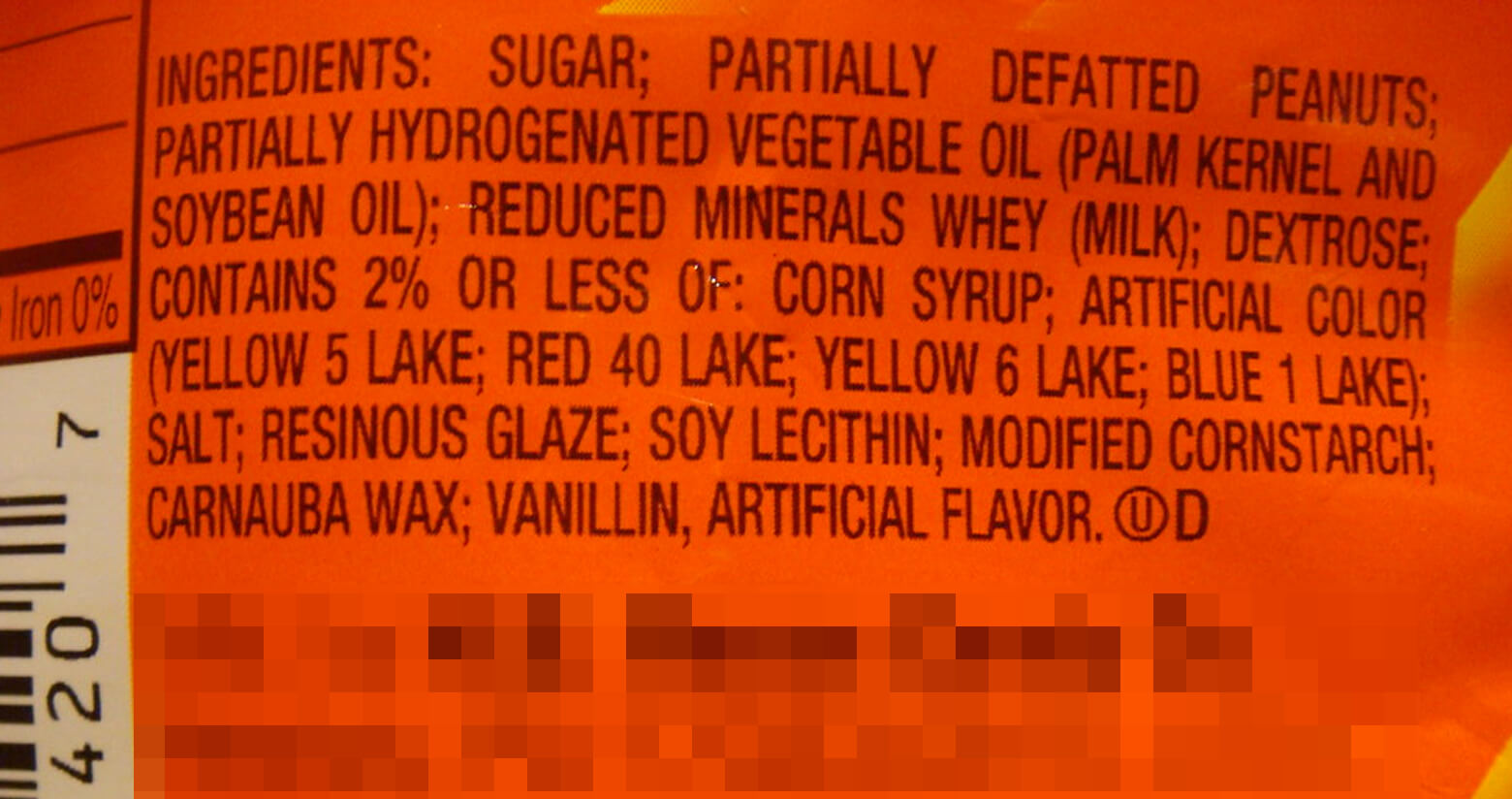

Factory-made sweets can lie on the store shelves without any special temperature regimes for a long time — from 6 months to 1 year, and some types in general up to three years. What’s the secret? The fact that the main ingredients of factory sweets are sugar and fat. This composition ensures that there are no problems with microbiology, since there is no water in the composition, and with the right ratio of ingredients and the addition of antioxidants, chemical processes can be slowed down as much as possible.

But don’t rush to «pump out» the water from the composition of your sweets! Water provides such a delicate, smooth, melting consistency of the filling, which cannot be created from sugars and fats. By reducing the amount of water and increasing the content of sugar and fat in the composition, we certainly increase the shelf life, but as a result, the craft product loses its attractiveness, which appears in a special texture, balance of taste and aroma, moderate sugar content and approaches mass- market.

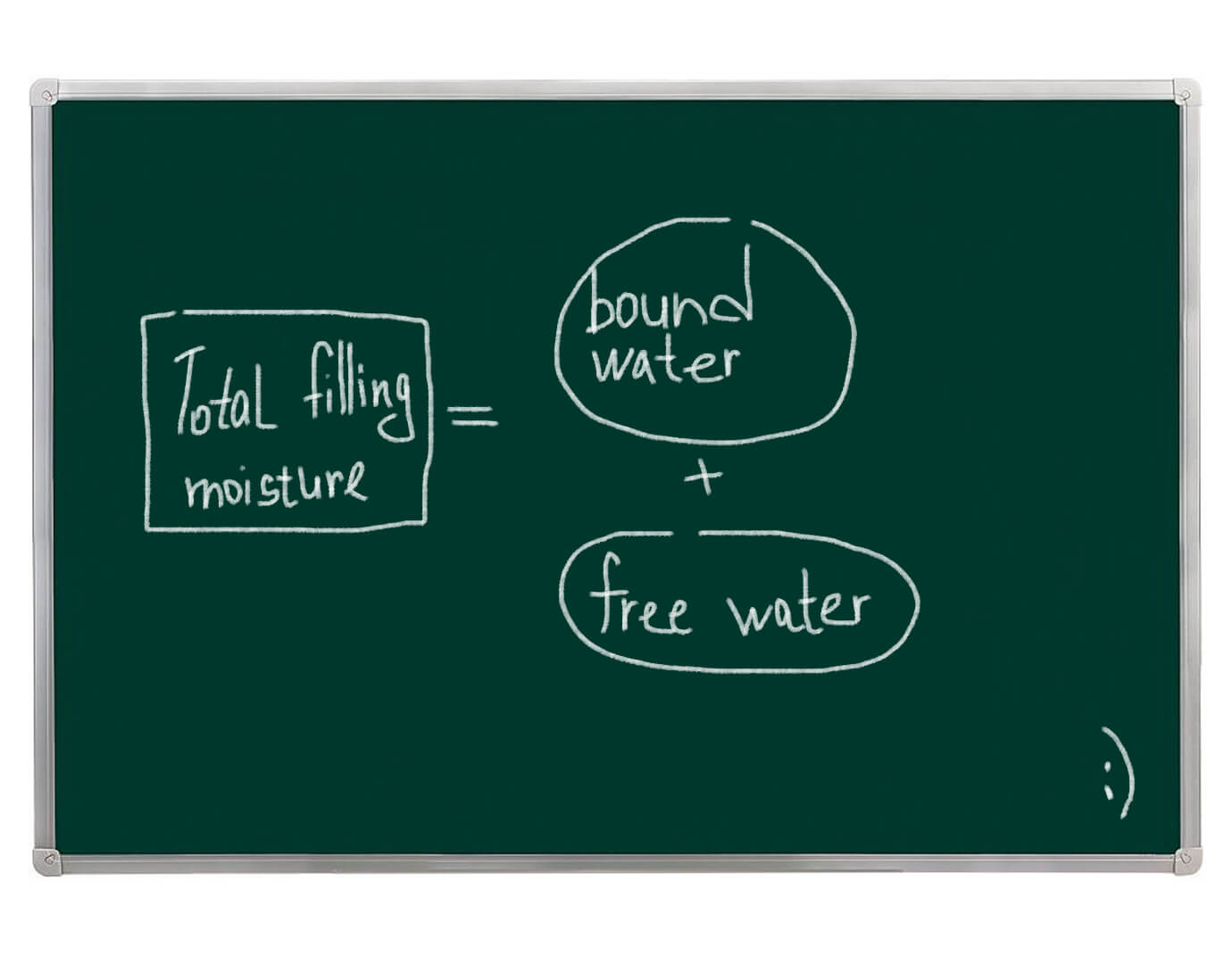

As part of the filling, we are not worried about all the water, but only the so-called «free», which is not associated with other substances. From here, pardon the pun, the concept of «water activity» flows, denoted by the abbreviation aW (water activity). The more free, unbound water, the more opportunities for the development of various kinds of bacteria, yeast and mold, which means that the shelf life of the filling becomes shorter.

Water activity is measurable. There are special devices — water analyzers (aW-meters). They allow you to calculate the free water in the filling. Expressed as aW in numbers ranging from 0 to 1, where water would have an activity value of 1 and the driest product would tend to a value of 0. To calculate the active water in the fillings you can use a special program Pro-Choc or Ganache Solution diagrams.

Why do you need to know all these numbers? In order to predict the shelf life of the candy. So, for example, a candy with aW 0.7-0.75 is more likely to retain all its properties for 60 days under certain conditions: storage temperature 10-13ºC, relative humidity about 70-75%, in a tightly closed package away from heat sources, light and strong odors.

There is another important water nuance that concerns the storage of sweets: active water is closely related to the concept of equilibrium moisture content. This means that the filling will give or take moisture until its aW-level is in equilibrium with the environment. In a room that is too humid, the filling will begin to absorb moisture, which will lead to the formation of free water, which will disrupt the stability of the filling and serve as a favorable base for the growth of microorganisms. In a room that is too dry, the filling will give off moisture and dry out, and its consistency will become rough due to sugar crystallization, as we wrote earlier. Sugar dissolved in water tends to crystallize back. Surely, many of you have come across this during the preparation of syrup: after complete dissolution in water, at some point, sugar begins to actively collect into crystals, which by no means want to dissolve. This is due to the fact that during boiling, the moisture evaporates so much that it isn’t enough to keep the sugar in mixture-form. To avoid reverse crystallization, glucose syrup, which has anti-crystallization properties, is added to fillings, syrups and other substances where there are sugars. If the room has a relative humidity level of 65-70%, then the filling with aW of about 0.7 will be stored as well as possible, since the moisture inside and outside is in balance, drying and sugaring, or vice versa, an increase in humidity will not occur.

A logical question arises: how to reduce water activity? To bind and neutralize so that it doesn’t become a condition for the development of microorganisms. To do this, various types of sugars are added to the emulsion fillings, which have hygroscopicity, the ability to retain moisture, prevent crystallization and other properties.

Let's get to know them better.

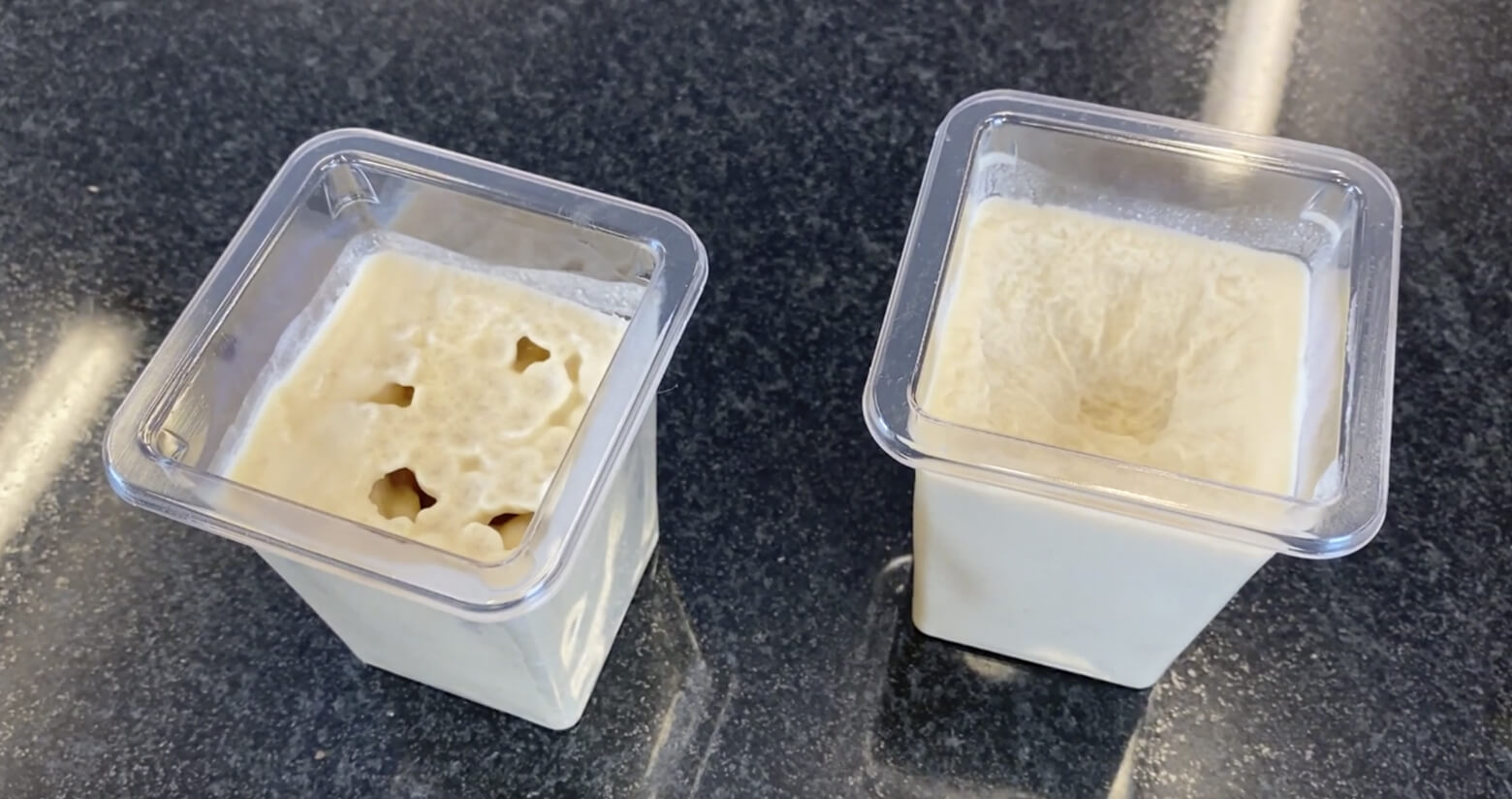

Two-layer fillings have a different composition and water level in the layers. The shelf life of such a filling will be less predictable due to the exchange of moisture between layers.

-

Glucose syrup.

The product of hydrolysis (decomposition) of starch. Its main property in fillings is anti-crystallization — it doesn’t allow sugar to crystallize back from the mixture, and also lowers the freezing point, which prevents ice crystals from forming in the product during freezing.

Glucose syrup is a clear liquid with a high viscosity and a medium level of sweetness.

Glucose syrup is a clear liquid with a high viscosity and a medium level of sweetness. -

Invert sugar.

It can be found on the market under the brand name «Trimoline». Invert sugar is obtained by inverting sugar (obviously). In fact, this is the same hydrolysis — the splitting of a sucrose molecule by heating the sugar syrup with acid and then neutralizing the reaction. Invert sugar is hygroscopic and retains moisture, thus preventing the filling from drying out.

Trimoline is an opaque white mass.

Trimoline is an opaque white mass. -

Sorbitol.

In short, it’s sugar alcohol, which is also used as a preservative and has properties similar to the above listed sugars.

Sorbitol (aka food additive E420).

Sorbitol (aka food additive E420).Unfortunately, there is no exact data on which sugars bind water to what extent and make it less free and active. In our opinion, sorbitol handles best with this. But there are no direct formulas on how much to add different sugars to bind water. There are several theories, but they all give different results in practice, so it won't work to calculate the shelf life on their basis.

It’s also difficult to say something specific about the optimal dosages of sugars, since everything depends on the recipe and the ratio of other ingredients in the filling. Of course, the more sugars in general, the better for preventing spoilage. But, as we said earlier, a large amount of sugar reduces the taste and brings the craft candy closer to the mass product. In addition, some types of sugars have side effects. For example, sorbitol has a laxative effect, so its dosage should be limited to about 3% of the mass of the filling. You should also take into account the different levels of sweetness that will affect the candy taste: invert sugar is 1.25 times sweeter than regular sugar, while glucose syrup and sorbitol are less sweet.

Fortunately, there is good news for those who have a headache from these problems with active water — fatty fillings.

Yes, the texture of the fat filling is not as melting as an emulsion, but it doesn’t have to fall to the level of the mass market if you adjust the sugar content and make the taste pleasant and rich, and not just sweet.

Fat fillings are stored from 2 to 12 months without a fridge.

Fats also undergo chemical changes during storage. Basically, these are various oxidative reactions that lead to a deterioration in taste (rancidity, the appearance of foreign flavors) and a violation of the consistency. Unsaturated fats, oils found in nuts and seeds that are often used in candy fillings, are the fastest to spoil. Completely stopping the oxidative processes won’t work. Usually the shelf life of candy with fatty nut filling is from 2 to 9 months, depending on the nut. Walnuts, pine nuts and pecans spoil the fastest, while almonds, peanuts, cashews and Brazil nuts last longer. On an industrial scale, various antioxidants are used to slow down the oxidation of fats: tocopherols, ascorbic acid, and others.

The main role in preserving the taste and texture is played by fat compatibility. In this context, lauric fats are most pronounced, which are subject to the so-called saponification (alkaline hydrolysis of fatty acid esters) much more than all other fats. The lauric type of fat is coconut oil, extracted from the pulp of coconut and the kernels of the fruit of the oil palm (palm kernel oil). Lauric fats are incompatible with cocoa butter, which is a non-lauric type of fat. In terms of candy expiration dates, this means that even though coconut flakes or paste will last about a year on average, and cocoa butter can last several years, a product made from a mixture of these two ingredients will have a significantly shorter shelf life due to migration of fats, softening of texture, deterioration of taste and appearance.

Before use, nuts must be roasted not only for taste, but also to avoid product contamination with bacteria or insect larvae that often live in nuts. Remember: roasting accelerates the degradation processes of fats: a roasted nut is stored worse than a raw one. Therefore, we do not recommend roasting nuts in advance.

In general, fat fillings are stored for 2 to 12 months without fridge.

To determine its expiration dates the rules are the same: if there is water — calculate aW, take the ingredients in the composition into account, manufacturing method, production and storage conditions (in a tightly closed package, away from sources of light, heat, strong odors, avoiding direct sunlight).

You need to remember one more basic thing: harmful bacteria surround us everywhere and the problem is not in their presence, but in their quantity. If a small amount enters our body, then the acidic environment of our stomach will destroy them with a high degree of probability, but if the same small amount enters a product where all the necessary conditions for their growth are created (water, air and temperature), then the number of bacteria will grow and can cause harm to the human body. Therefore, the strict rules that are prescribed by the great and terrible HACCP have a good reason. They really need to be observed in order for your product to be safe.

Here are the main theses:

-

All filling ingredients must be fresh;

-

It is necessary to subject to mandatory heat treatment (pasteurization, sterilization, roasting) all the ingredients for the filling. Nuts, dried fruits, sublimates and spices are potentially microbiologically «dirty» products;

-

The finished filling should be glazed in chocolate as soon as possible. Bacteria and mold spores live around us and, even getting into the pasteurized cooled ganache, they begin to grow. Peak growth occurs at a temperature of 40-60ºC. Therefore, it’s important to quickly cool the finished ganache and stabilize the filling in order to close it in the candy shell, because the longer the filling is left open, the greater the risk of infection. All this is another weighty argument in favor of filling pre-crystallization. Yes, it’s not a necessary condition for the manufacture, but it significantly reduces the time of ganache ripening. It’s more convenient and faster to pre-crystallize the filling with cocoa butter silk. You can find what it is and how to use it here.

This is the conclusion that can be drawn from the above. Life is dangerous and unpredictable, and product safety is affected by too many factors, each of which requires serious, in-depth study. You cannot determine the expiration date of your chocolate products based only on the composition of the ingredients. When making fillings that contain water, you will need to consider the activity of the water and reduce it if necessary. Fat fillings are easier, but you still need to take into account that some nuts spoil faster than others, as well as fat compatibility and remember to roast the nuts before use. And, of course, don't forget about hygiene — «wipe the slate clean».

Just a moment...

Just a moment...