Why is chocolate shiny or not shiny?

Tags:

Have you ever thought that the word «shine» is often used in a positive way? Shining star, rise and shine, shine like new money, take a shine — all idioms emphasize exceptional quality. And don’t tell us about Stanley Kubrick’s «The Shining», better sing «shine bright like a diamond» as Rihanna do!

Why does chocolate have to shine? Clothes count for first impressions, so a beautiful shine is no less important parameter for chocolate than the lack of sugar bloom, stains and deformation.

Today we will tell you why chocolate shines and how to achieve a beautiful natural shine.

In order to understand why chocolate shines, let's ask physics for help. Or rather, one of its branches — optics.

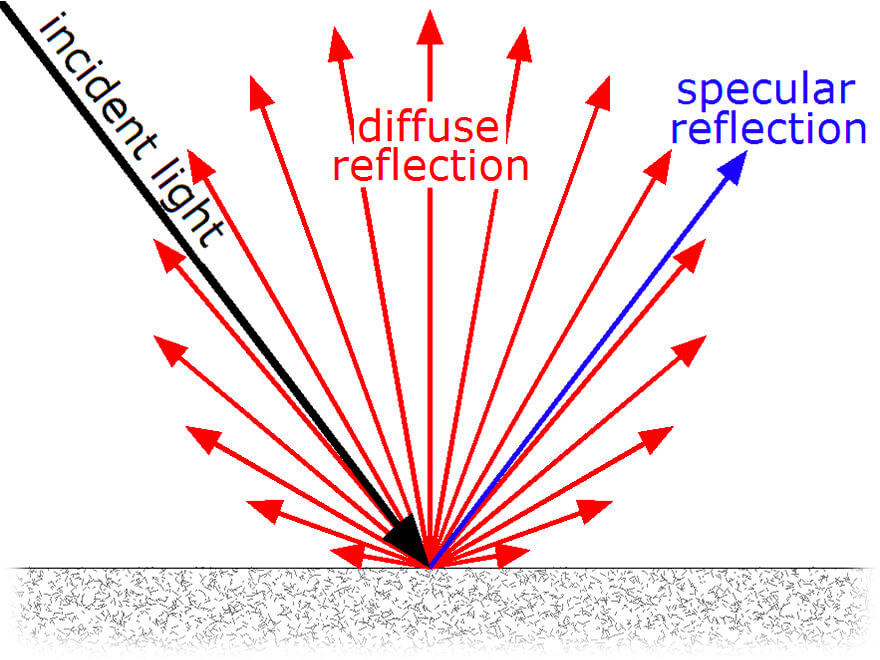

Shine (or gloss) is an optical property which indicates how well a surface reflects light in a specular (mirror-like) direction. It is one of the important parameters that are used to describe the visual appearance of an object. The factors that affect gloss are the refractive index of the material, the angle of incident light and the surface topography.

Apparent gloss depends on the amount of specular reflection — light reflected from the surface in an equal amount and the symmetrical angle to the one of incoming light — in comparison with diffuse reflection — the amount of light scattered into other directions. Can a coconut shine? Nope. But if you polish it well, it will shine like a mirror.

No matter how extraterrestrial chocolate is in taste, it exists in our reality and obeys the laws of physics. Before the molding stage, chocolate is in a liquid state, so while solidifying, it copies the relief and texture of the surface with which it contacts at the moment of solidification with an accuracy of 99.9%. So…

Despite the popular belief, tempering is not the only factor that affects chocolate shining. Chocolate itself doesn’t shine, it’s quite porous, although this is not visible to the naked eye. Shine appears only after molding and only in the place where the chocolate contacts with a smooth surface: mold, acetate sheet, etc. A glossier surface means the chocolate will shine more. For a beautiful shine, a mold with a perfectly smooth inner surface is required. Even non-pre-crystallized chocolate will shine after such a mold, but not for long — after some time an unstable crystal lattice will kill all the shining.

The mold material plays an important role in this: the harder it is, the easier it is to make a smooth inner surface. Therefore, plastic and polycarbonate are used for «shining» molds. When choosing silicone molds with a smooth surface, you can also achieve the perfect chocolate shine, but most often silicone molds simply don’t have such a surface, because silicone is a soft and porous material, which is quite difficult to achieve smoothness when making molds. In addition, a smooth surface is not the only parameter that determines a good silicone mold: the thickness of the walls and the quality of the silicone itself are also important. Therefore, we still do not recommend using silicone molds for making bars, figures or other products where the shine of the chocolate surface is important.

Believe it or not, mold design is important too. In addition to the molds, after which the chocolate product will have a smooth glossy surface, there’re also molds with a micro-relief. The rough texture of the mold, intended by the designer, gives the chocolate a more matte surface that is shiny, but not as much as glossy. There is nothing wrong with this, but if you want to give your product an extra shine, you can use glosses. For example, capol (Capol® 5199) or shellac (Shellac Е904).

By the way, our good friends have a huge range of molds for every taste. You can also order molds with your own unique design (for example, with your own logo).

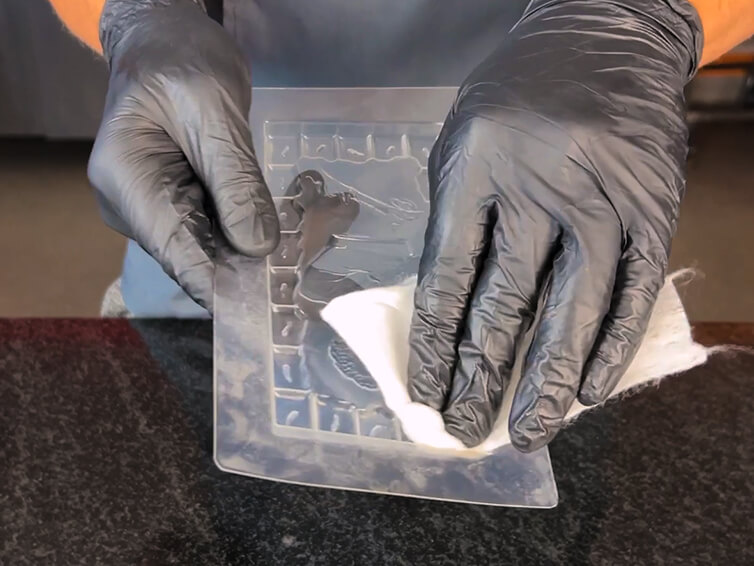

The next important thing is care. Molds made of soft PET plastic quite easily collect all the scratches and roughness, which will definitely be reflected on the surface of the chocolate, as a result of which it will lose its appetizing shine. To avoid the appearance of defects on the mold, we recommend carefully wiping new or used molds from dust or other debris with a soft, lint-free cloth (for example, microfiber). Polycarbonate molds are more difficult to scratch, but they too can be damaged using abrasive detergents or rough dish sponges.

After prolonged mold usage in several chocolate pouring cycles, a thin layer of cocoa butter remains inside it. No need to get rid of it in the name of purity, because such a layer of cocoa butter will give the chocolate a great shine the next time you use the mold. But before use, the mold must be preheated to about 28ºC and wiped with a dry, lint-free cloth so that the thin layer of cocoa butter warms up and melts for better gluing. If nothing is done to the mold after each pouring, the cocoa butter will not adhere well to the new casting, which will lead to haze on the surface of the chocolate and loss of shine.

A good mold with a smooth inner surface and careful cleaning is great, but if you neglect the correct crystallization of chocolate, then its surface will acquire ugly spots that may or may not shine, but in any case will spoil the impression of your product.

We won’t deep dive into this topic here, because we’ve already analyzed all crystallization errors in detail in another material.

![]()

If your chocolate doesn’t shine, then you shouldn’t blame the quality of the pre-crystallization, because even poorly pre-crystallized chocolate will shine at first if it’s cast into a glossy mold with a perfectly smooth surface inside.

![]()

The molds material is important. Molds made of PET plastic or polycarbonate are easier to give a glossy smooth inner surface.

![]()

Molds with internal micro-relief are designed to give the product a special pattern, due to which the surface can be matte. In this case, glosses can be used for extra shine.

![]()

Take good care of your molds. Do not use a cloth that may leave lint or scratches behind. Soft microfiber is the best choice.

![]()

And do not neglect the correct cooling — the final appearance of the product still greatly depends on it.

Just a moment...

Just a moment...