Melangeur with spiral grooved stones. You wouldn't grind any other way.

Tags:

This article contains ads. Not because we got paid (nah), but because it's our duty to speak out loud about the things we've learned that also work great and help manufacturers and artisans achieve better results faster. That's why we run this journal.

Have you ever wondered why the millstone groove of most melangeurs looks like this:

No? By the way, this little detail is very important — the speed and quality of grinding depends directly on the stone millstones. The type of groove you can see above is called «circular» or «straight». Simply put, the groove is parallel to the course of the stone millstone. Like rings on the finger.

Yep, almost all melangeurs that you can find now have a circular groove. This form became traditional in some way. It is easy to carve it and for many centuries there were no issues with it. No one cares about the look if it works. But is circular groove really this effective?

Being a chocolatier means working not only with cocoa, but with the other products. Personally, our melangeur with a circular groove fails a bit with «capricious» ingredients. For example, the grinding of coconut flakes remains coarse even after 2-3 days in the melangeur. Maybe the coconut is bad and we bought it from some cursed tribe? Nope. After talking with fellow chocolatiers, we learned that many people face such problems. Therefore, we decided to dig into this issue.

So, what's the point? During the rotation of millstones with a circular groove, the contact spot with the bottom, in which the mass is ground, does not change. So the mass is ground well only in one specific place. Take a look:

Friendly engineers from KADZAMA drew our attention to this detail. Due to the fact that in addition to the equipment manufacturing, they also monitor its work on the production of their customers, they have the opportunity to quickly collect feedback from technologists and chocolatiers. Chocolate «Big data» indeed.

Well OK. Knowing the problem is great, but the problem still exists. Hush! Don't spoil the surprise. KADZAMA collects data for a reason: to use it in future inventions.

During the rotation of millstones with a circular groove, the contact spot with the bottom, in which the mass is ground, does not change.

Here they wanted to answer the question: how to increase the contact spot so that the grinding process becomes more efficient? And the answer is a new type of groove — «spiral».

The idea of spiral groove (aka «diagonal groove») is increasing the intensity of grinding the product with grinding discs of melangeurs. According to KADZAMA’ patent, the grinding disc of the melangeur is made in the form of a cylindrical part with grooves cut on its surface. The path of these grooves matches the helical lines, and the axis matches the axis of the cylindrical surface.

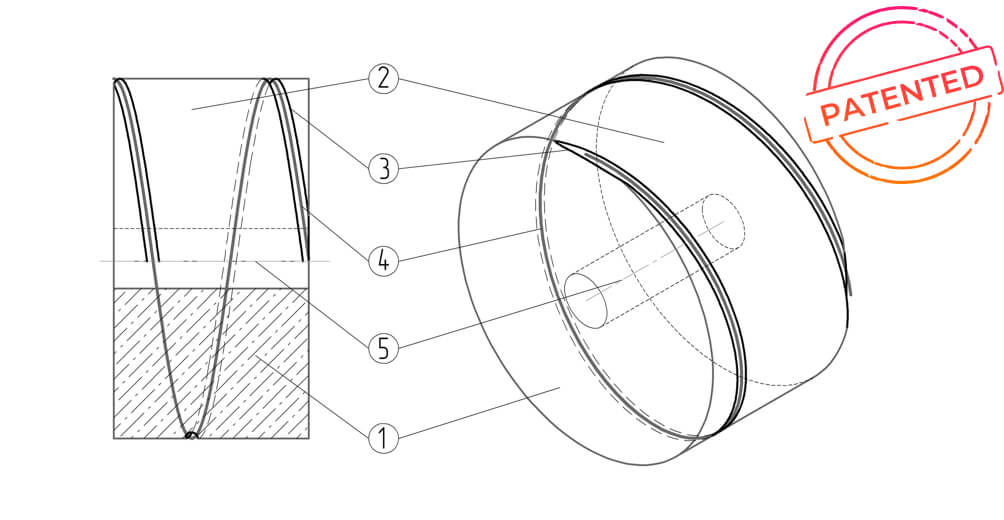

This diagram shows a variant of the melangeur grinding disc with a spiral groove. The numbers mean the following:

1. Cylindrical grinding disc;

2. Cylindrical disc surface;

3. Helical groove;

4. Helix (matches the groove path);

5. Axis of helical lines (matches the cylindrical surface axis).

Damn, I realized that caused you some «vietnam flashbacks» with this boring high school’ science class type shit. I understand that as a chocolatier you don’t care about all this science stuff and, first of all, you are interested in how this innovation will affect your work. Okay, I’ll show you.

The spiral groove sets the direction of the mass and grinding vector, making it tighten under the millstones more intensively. Under such conditions, grinding becomes much more evenly and more productively due to the fact that the effective contact spot in the area between the mass and stones becomes larger and dynamic (not static, as in the case with a circular groove).

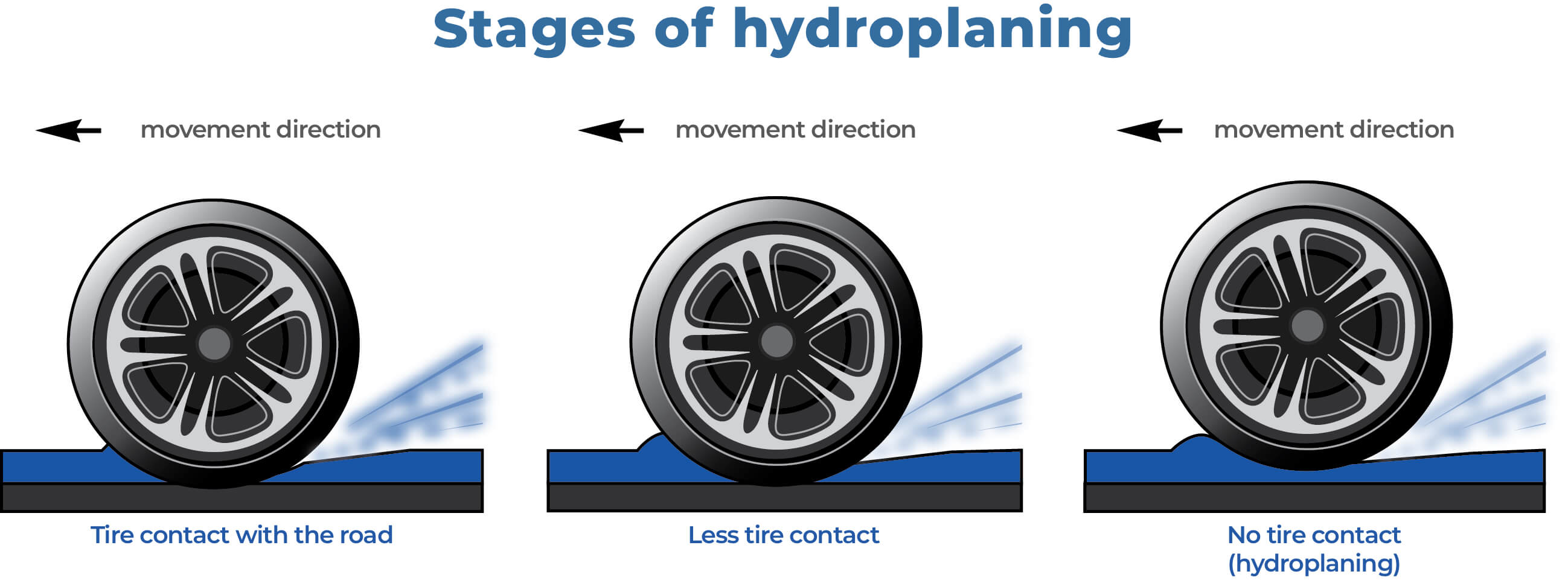

Okay, let's try to compare with something regular. Are there any car enthusiasts among our readers? Good! Then you are probably familiar with the hydroplaning thing. It occurs when a layer of water builds between the wheels of the vehicle and the road surface, leading to a loss of traction that prevents the vehicle from responding to control inputs. Water-repellent car tires have a special diagonal «rain pattern» («christmas tree» is the most popular), designed to throw water from under the wheels back and to the sides, thereby preventing the formation of such a dangerous hydrodynamic wedge.

The spiral groove sets the direction of the mass and grinding vector, making it tighten under the millstones more intensively.

Imagine that tires are millstones, a spiral groove is a tire pattern, and water is chocolate or any other mass. Within the closed bowl of the melangeur, the spiral grooves push and pull in the mass at the same time, making the grinding more uniform throughout.

Well, who believes in bald terms? Here are the tests!

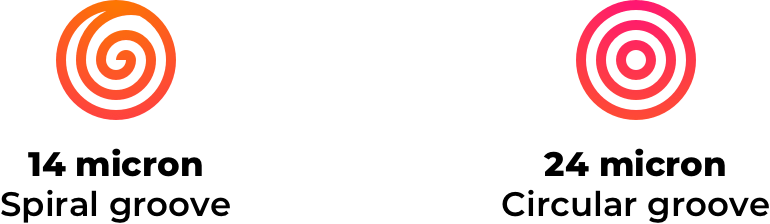

For the first one, we loaded the same milk chocolate recipe into two melangeurs with different grooves. After a day of grinding the mass at the same rotation speed and stones pressure, it’s clear that the millstones with a spiral groove handled the grinding better. We took measurements with a micrometer, which showed that the particle size in the mass from a melangeur with a spiral groove is almost 2 times smaller:

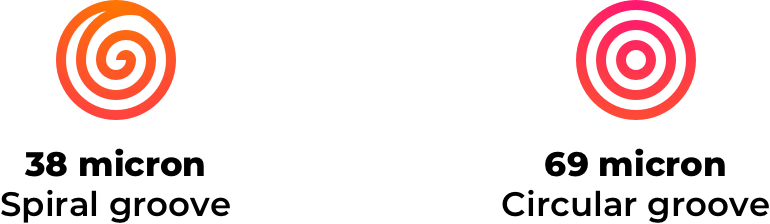

Let's complicate the task with the recipe of coconut spread. Coconut flakes, butter and sugar in the same melangeurs with the same conditions as in the first test. A day later, we got the perfect spread with a delicate creamy consistency in a melangeur with a spiral groove. Ringed stones did it worse. But what Mr. Micrometer thinks?

Our findings are clear: millstones with a spiral groove really grind masses more efficiently than millstones with a circular groove.

And since melangeurs with a spiral groove are in stock, there are satisfied customers already. So not only we think they are lit.

Hell yes, you read it right — you can already buy it. At the same price, not a penny more. A perfect time to buy, don't you think?

CHOCOLOGY highly recommends!

Just a moment...

Just a moment...